In industrial maintenance environments, an industrial mechanic tool cart is often one of the most frequently used pieces of equipment.

However, many mechanics and maintenance teams begin to notice the same problems after 1–2 years of use:

- Tools keep increasing, and storage space becomes insufficient

- Drawers start to feel “strained” due to limited load capacity

- Casters deform, making movement difficult or even unsafe

- A tool cart that once worked well gradually becomes a bottleneck to efficiency

This is not an isolated case—it is a very common growth-related issue in industrial maintenance operations.

1. Common Problems After Two Years: Where Do They Begin?

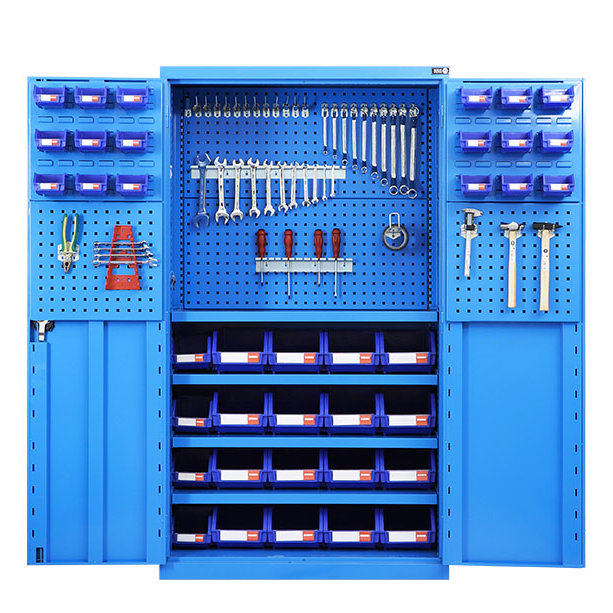

1️⃣ Tool Growth Outpaces the Original Layout

As equipment upgrades and processes become more complex, the number and type of tools increase:

- More power tools

- Heavier specialized maintenance tools

- Spare parts and consumables that require centralized storage

Original single-column or open-frame industrial mechanic tool carts often can no longer support these growing storage demands.

2️⃣ Insufficient Drawer Load Capacity Affects Safety and Efficiency

Many early-stage tool carts are designed with limited drawer load capacity:

- Drawers become difficult to open when fully loaded

- Slides may sag after long-term use

- Heavy tools cannot be stored centrally

When drawer load capacity no longer matches real-world tool weight, efficiency drops—and safety risks increase.

3️⃣ Deformed Casters Increase the Cost of Mobility

In industrial environments, tool carts are moved frequently:

- Uneven workshop floors

- Long-term full-load conditions (tools may even shift or fall out)

- High daily usage intensity

Standard casters under long-term heavy load often suffer from:

- Deformation

- Increased rolling resistance

This directly undermines the core value of an industrial mechanic tool cart as a mobile tool platform.

2. The Solution: It’s Time to Upgrade Your Industrial Mechanic Tool Cart

When these issues appear, repeatedly repairing an old tool cart is rarely the best solution.

Upgrading to a true industrial-grade tool cart designed for higher load and long-term use is often the more effective choice.

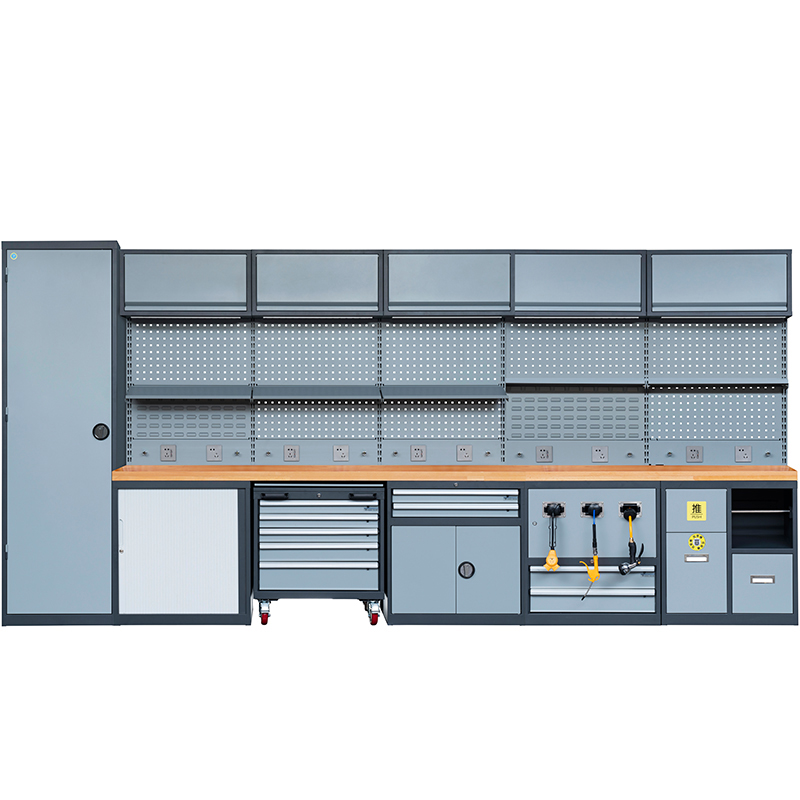

Solution 1: Double-Column Tool Cart

Recommended for users who:

- Handle many tool types with varying sizes

- Need a combination of drawers and cabinet storage

- Work in industrial maintenance or equipment service environments

Key advantages:

- Double-column cabinet structure for improved overall stability

- Strong load capacity without the need for additional DIY reinforcement

- Drawers for high-frequency tools, cabinet space for large or special equipment

- Cabinet doors customizable (single door, double door, or internal layout options)

This configuration is ideal for users upgrading from a standard industrial mechanic tool cart.

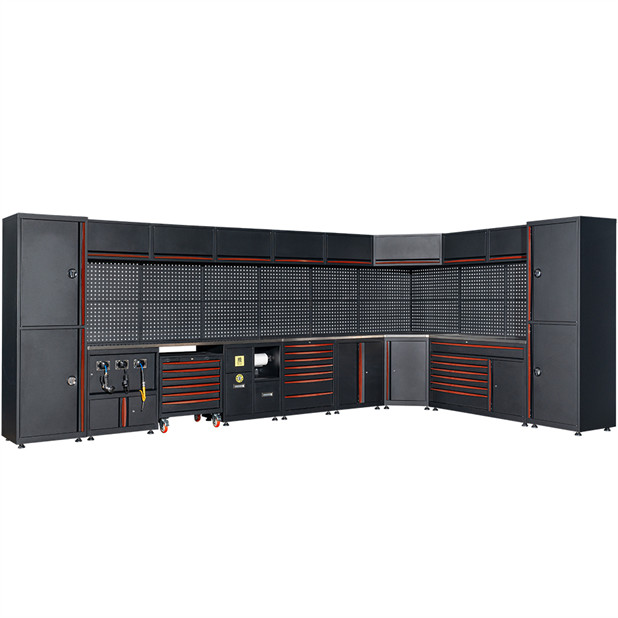

Solution 2: Triple-Column 18-Drawer Heavy-Duty Tool Cart

High-density drawer storage solution

Recommended for users who:

- Have a continuously growing tool inventory

- Emphasize tool classification and workflow efficiency

- Need centralized storage for heavy tools

Key advantages:

- Triple-column structure greatly increases total storage capacity

- Customizable high-density drawer layouts for maximum space utilization

- Heavy-duty slide systems supporting higher per-drawer load capacity

- Optional internal dividers to fit tools of different sizes

This is the ultimate upgrade solution for high-intensity industrial mechanic tool cart applications.

3. Why the Upgraded Experience Feels Completely Different

After upgrading to a higher-spec industrial tool cart, users typically notice:

✔ Tools are no longer “crammed in,” with clear classification

✔ Heavy tools are stored centrally while drawers remain smooth

✔ Heavy-duty casters provide stable, effortless mobility

✔ No need for DIY reinforcements to increase load capacity

This upgrade is not just about replacing a tool cart—it enhances the efficiency and safety of the entire maintenance system.

Conclusion: An Industrial Tool Cart Should Grow With Your Work

If your industrial mechanic tool cart has been in use for two years and now shows signs of limited space, insufficient load capacity, or poor mobility, it doesn’t mean you made the wrong choice.

It means your work requirements have evolved.

Choosing an industrial tool cart with:

- A more stable structure

- Higher load capacity

- Customizable layouts

is essential to support the next stage of high-intensity maintenance work.

If you are considering upgrading your industrial mechanic tool cart, now is the right time to plan for a solution that truly matches your workload.