Steel specification and durability analysis

When discussing the durability of tool trolleys, the first thing noticed is the material, generally used industrial grade tool carts usually use Q235 specification steel, which has moderate carbon content, good strength and toughness, and is better suited for the storage of heavy tools and equipment.

Some higher-level workshop tool trolleys may use 3mm thick steel plate to enhance the structural strength, so that the tool trolley can be used stably in the workshop or factory and other frequent use scenarios.

What are heavy duty casters? How is it tested?

Heavy Duty Casters: Load-bearing wheels designed for high-load environments, they typically have stronger construction, greater bearing capacity and wear resistance.

Heavy duty casters have a static average load capacity of 1000kg, with some load capacities exceeding this weight.

To ensure that the performance of casters can meet the requirements, merchants will choose the casters for dynamic load test and impact resistance test:

Dynamic load test: simulate the situation of casters rolling and traveling for a long time, check its stability and wear resistance under high load conditions.

Impact resistance test: To evaluate the caster’s structural toughness and capacity to tolerate abrupt external forces, it is repeatedly struck with a heavy item.

Wheel breakage or distortion in real use can be minimized by passing these two simple tests.

How to avoid bent drawer slides and broken wheels?

One of the most common problems in tool cart use is bent drawer slides and broken wheels. This is usually due to inadequate design or poor choice of materials. To avoid these types of problems:

Choose drawer slides with a strong two-section rail design. This helps the weight spread evenly, making them able to carry more load.

The load capacity can generally reach 150kg for a single drawer track.

Choose slides with high-strength bearings or ball bearings to ensure smooth operation and reduce wear and tear. Generally 10 groups of high quality bearings are used and equipped with rail joints.

Make sure the size, material, and weight limit of the casters fit the actual load of the tool trolley.

Comparison of different tool trolley wheel load capacity

Light: 200kg Multi-functional tool trolley suitable for auto repair

Medium: 500kg Suitable for flexible mobile tool design in workshop

Heavy: 1000kg Suitable for industrial use and placing heavy equipment for storage

Comparison of Scratch and Corrosion Resistance of Steel Grades and Coating Types

Powder Coated Steel:

Higher scratch resistance, strong surface hardness, can effectively reduce scratches.

Great resistance to rust, especially in wet places or where corrosion is common.

Galvanized steel:

Excellent in corrosion resistance, especially against chemicals or salt.

The galvanized layer is thinner. This means it can get scratched easily and show wear over time.

Tests show that powder coating works well where machines or tools are often used. Galvanized steel is better for places with harsh chemicals or high humidity.

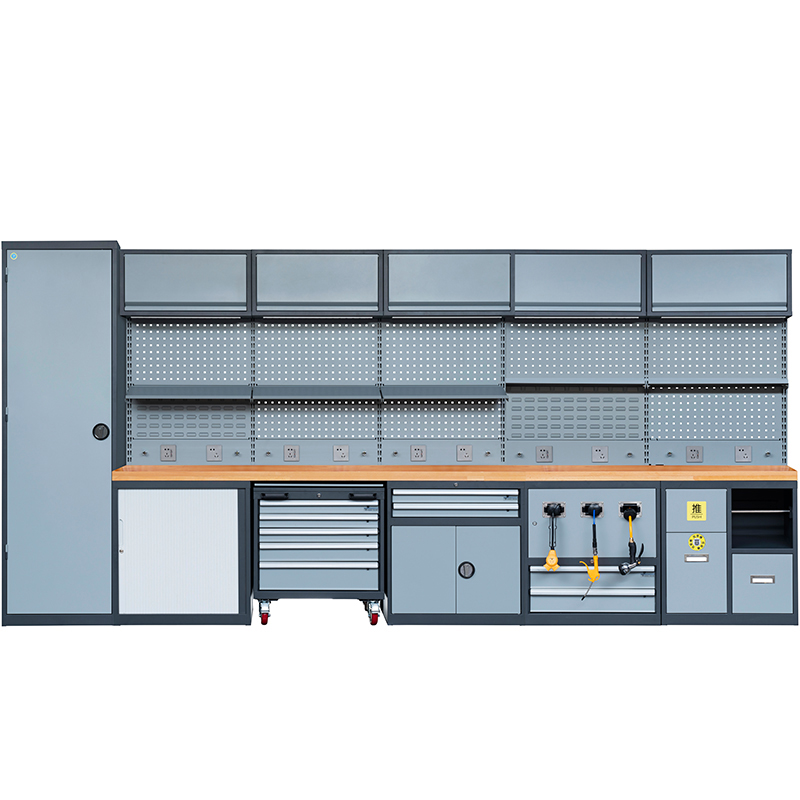

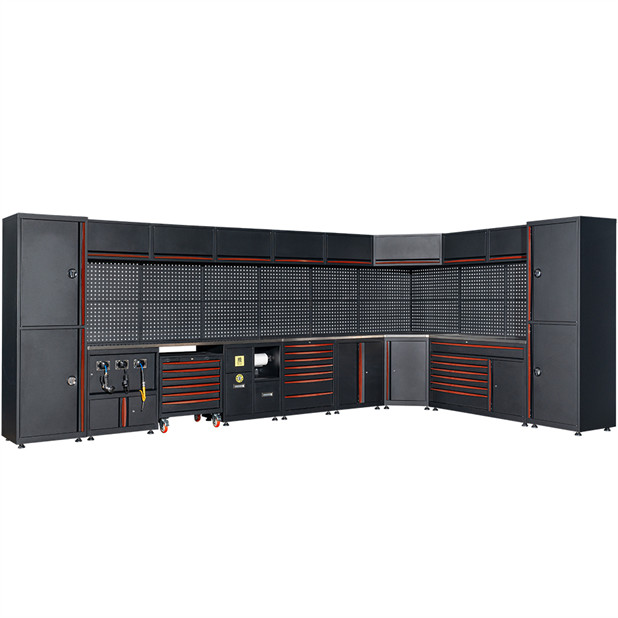

Flexibility in choosing the size of the workshop trolley and the number of drawers is essential when organizing the shop floor and optimizing the workflow.

You can change most platform workshop trolleys to fit your needs. This includes size, drawer layout, and how many drawers there are.

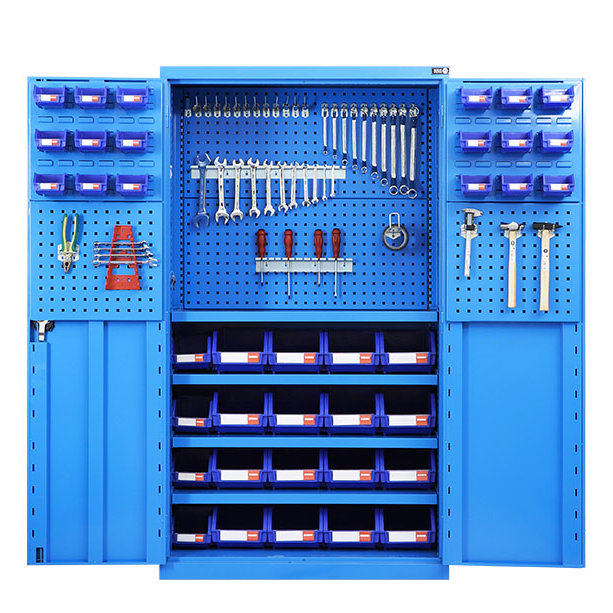

You can make drawers deeper or wider to hold bigger tools based on what you need. You can also add dividers in the drawers to organize smaller tools and accessories.

If you customize your tool cart for your job, you can make it easier to reach your tools and save time finding them.

Multi-functional extension design

To make the tool cart better, sellers will offer extra parts. These parts will help organize tools and use space more efficiently.

1. Additional pegboard: allows flexible hanging of tools for quick identification and access.

2. Small operating table: provides additional temporary working space for quick on-site repairs or parts assembly.

3.ABS desktop or stainless steel desktop: ABS is non-slip and durable, making it good for general use. The stainless steel desktop is easier to clean and better for areas with oil or chemicals.

4.Different characteristics of the drawer handle to meet the needs of different people:

Magnetic panel pulls: Realize quick and convenient opening and closing, while preventing accidental opening, with higher safety.

One-piece molded handles help keep parts tight and unbroken. They make the handle stronger and lower maintenance costs.

All-plastic integrated flap labeling slot: labeling slot and drawer are integrated, placing labels to facilitate the classification and management of tools, easy to locate tools.

The overall modular design of the tool cart not only improves functionality but also enhances the ability to adapt to different task scenarios.

Real user evaluation and field cases

Actual user feedback provides reference value for us to optimize the tool cart.

Case 1: standard model tool cart feedback

standard model workshop trolley in the workshop after three months of use, the use of three months of customer feedback to us

tool cart overall mobility is good, saving the maintenance staff to go back and forth to save the energy, and significantly improve the efficiency of the maintenance staff.

Tools placed in a clear location can quickly access the tools, shorten the search time caused by the chaotic storage of tools.

Case 2: Feedback on the first use of a customized tool cart for an overseas customer

We recently delivered a customized tool cart to an overseas customer and immediately received positive initial feedback:

The customer recognized the quality of our customized cart and affirmed our ability to complete the implementation of the customized solution.

The drawer system opens easily and has a lot of space. It is made to hold big tools that need to be stored.

The tool cart has universal casters that allow it to move easily in any direction. The casters can also be locked, which keeps the cart stable when it is not in use.

How does a high quality tool cart reduce long term costs?

Use strong materials: Good quality steel, tough wheels, and strong build make tool trolleys last a long time. This helps cut down the costs of replacing them often.

Organizing tools and storing them safely can help prevent damage. This can lower the costs of fixing or buying new tools after they get dropped, bumped, or lost in messy piles.

Improve work efficiency: When employees have tools that are organized and easy to reach, they can do their jobs faster. This boosts productivity and lowers labor costs.

Reduce Indirect Costs

Production delays happen because tools are not clearly classified. This makes it hard for employees to find the tools they need. As a result, operations run less efficiently and many work hours are wasted.

More safety accidents: If tools are not organized or are in the wrong place, they can cause accidents. This will raise the costs of dealing with these accidents and the insurance costs related to them.

Higher tool maintenance costs: Bad tool storage can cause more tool damage. This leads to more maintenance and replacement costs.

Increase employee satisfaction and health value

Ergonomic design helps workers feel less tired and boosts their productivity.

Superior mobility reduces unnecessary trips, saving time and energy.

Productivity can be greatly increased with a decent workshop trolley. Durability of materials, design, and user experience are other crucial factors. A long-term cost-benefit study shows that buying a tool trolley has many benefits. It can help reduce costs and improve worker satisfaction.Selecting a tool trolley that meets the requirements of professional workshops or repair rooms is a smart investment.