When selecting tool cabinets, people usually consider how well the drawers meet their storage needs and how smoothly they glide. However, they often overlook the drawers’ specific load-bearing capacity. Many suppliers label their products as “industrial-grade tool cabinets,” but the drawer slides only support a maximum load of 45 kg (100 lbs). This significantly reduces the lifespan of such cabinets. I have researched tool cabinet brands that can withstand use by two generations, with an extremely long lifespan and minimal risk of damage.

In this blog, we will explain the types of drawer slides used in tool cabinets. If you plan to purchase heavy-duty tool cabinets for your workshop, this guide will help you make an informed decision.

The most common types of drawer slides used in tool cabinets are:

1. Ball-bearing slides: Also known as three-section drawer slides. They are generally suitable for low-frequency use in residential settings and can withstand approximately 30,000 opening and closing cycles. However, they are not suitable for heavy tools and are prone to wear and tear.

2. Ball Bearing Slides: Also known as single-track slides. They are generally suitable for office furniture, workshops, and maintenance areas with a high frequency of use. They can withstand 40,000 to 50,000 cycles, support up to 220 lbs (100 kg), allow drawers to open up to 85%, and provide stronger load-bearing capacity and smoother operation.

3. Heavy-duty tracks: Also known as dual-track slides. Drawers can open fully, supporting approximately 330-440 lbs (150-200 kg). They are generally suitable for factories with heavy use for storing industrial equipment or heavy-duty tools. They are capable of withstanding 80,000 high-frequency opening and closing cycles and feature high strength and durability.

Why are drawer slides so important in tool cabinets?

Even if a tool cabinet’s frame is extremely sturdy, poor-quality drawer slides can pose safety hazards.

1. When fully loaded, the drawer may not slide smoothly or may get stuck.

2. Over time, under a full load, the drawer may bend or deform, or its load capacity may decrease.

3. The product’s lifespan is shortened, requiring frequent replacement and increasing financial investment.

How can you ensure smooth drawer sliding?

Consider the following points to ensure smooth drawer sliding:

1. Choose suitable slides. Conduct a simple assessment based on the weight of your tools and select matching drawer slides. For example, prioritize heavy-duty tool cabinets for durability and load-bearing capacity.

2. Proper Installation: Properly align the slides during installation to prevent jamming. Misaligned slides can cause friction between the drawer and the cabinet, which affects smooth movement.

3. Regular cleaning: Over time, especially in industrial environments, dust and debris can accumulate on the drawer slides and obstruct smooth movement. Clean the slides regularly with a clean cloth or cleaning agent to maintain smooth operation and extend their lifespan.

4. Lubrication: Use an appropriate lubricant to improve the smoothness of the tracks. However, avoid grease- or oil-based lubricants, as they can cause dust to stick more easily.

5. Avoid overloading drawer tracks. Distribute the weight evenly in drawers to prevent premature wear and bearing damage caused by excessive loads.

6. Replace worn tracks promptly. Inspect the tracks regularly for wear and tear. If they are severely worn, replace them promptly to avoid safety hazards and maintain durability.

Why do our tool cabinets stand out?

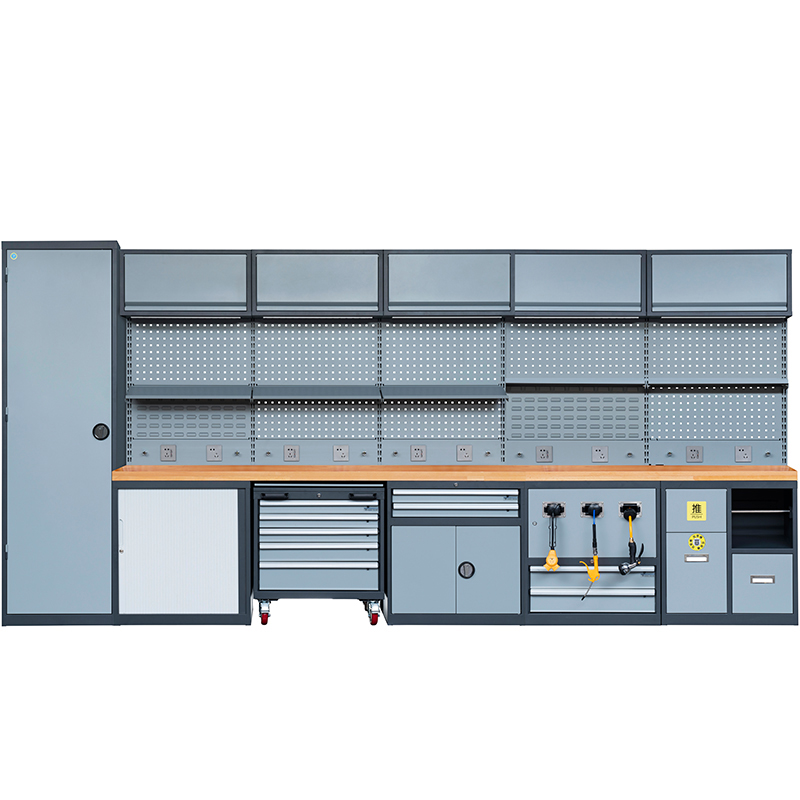

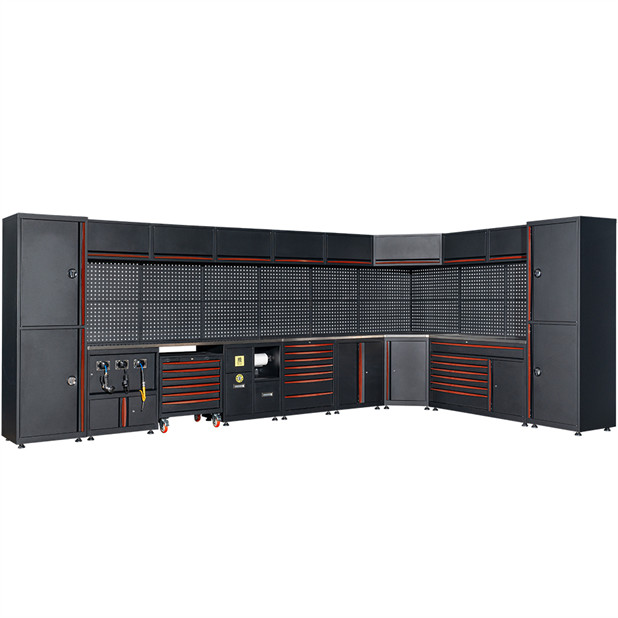

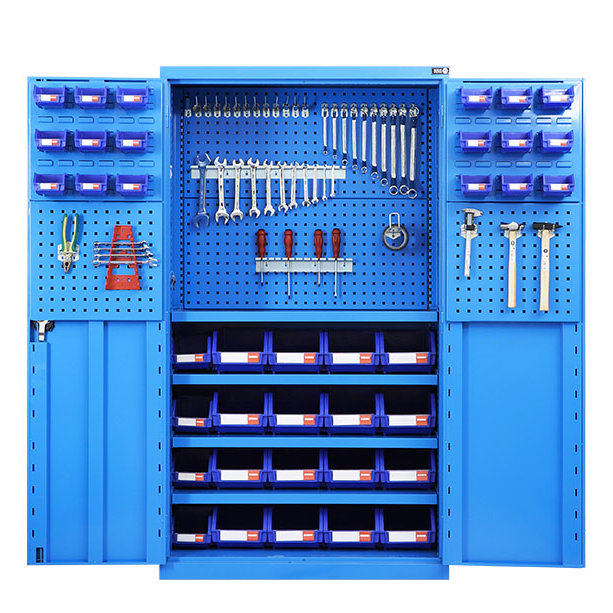

When manufacturing tool boxes, we consider the needs of different customers and design customized solutions.

1. High-load capacity drawers that can hold heavy equipment and industrial-grade tools.

2. Heavy-duty slides allow the drawers to open fully for easy access to tools. We will soon introduce a rubber-coated solution to address the excessive noise issue caused by bearing metal sounds in industrial-grade tool cabinets.

3. Integrated locks with a self-locking system ensure site security.

4. The patented anti-tip design prevents safety issues caused by retrieving tools.

5. The product is durability-tested to withstand tens of thousands of drawer openings and closings without failure.

Drawer slides are essential for optimal tool cabinet performance. Understanding the different types of slides—ball bearing, ball bearing, and heavy-duty—allows you to select the appropriate cabinet for your needs.

If you are looking for a heavy-duty, durable tool cabinet with precision-engineered drawer slides, explore our selection of cabinets, carts, workstations, and storage solutions designed for professionals in Europe and other regions.

Contact us today to find the perfect tool storage solution for your workshop.