In manufacturing plants, maintenance workshops, warehouses, and outdoor industrial sites, storage areas are often exposed to dust, oil, corrosion, vibration, heavy loads, and frequent daily use. Standard household or light commercial cabinets simply cannot perform reliably under these conditions.

So what defines a true Industrial Storage Cabinet for harsh environments?

Let’s take a closer look.

1. Heavy-Duty Construction for High-Intensity Operations

The biggest challenge in industrial environments is continuous heavy loading.

True industrial storage cabinets are typically built with:

Thick steel cabinet bodies

Fully welded or reinforced assembled structures

Strengthened bases and vertical supports

These features ensure long-term stability even under constant weight, frequent drawer operation, and equipment vibration. They are ideal for storing:

Heavy tools

Industrial components

Maintenance equipment

Power tools and accessories

Such products are commonly known as Heavy Duty Storage Cabinets and are essential infrastructure in factories and workshops.

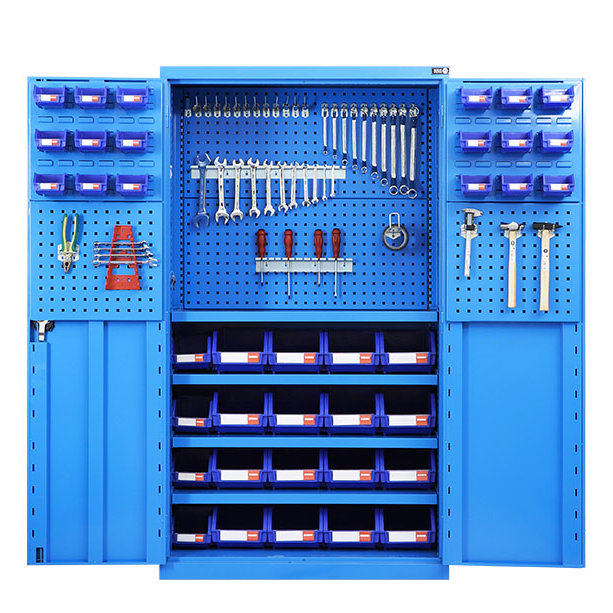

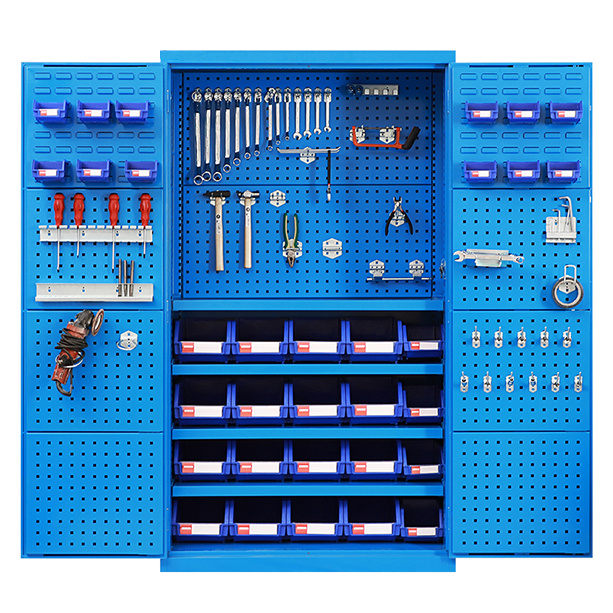

2. Multi-Drawer and Compartment Design for Higher Efficiency

In harsh industrial environments, searching for tools wastes valuable time.

Professional industrial cabinets usually feature:

Multi-drawer systems

Compartmentalized storage layouts

Adjustable shelves or dividers

This organized structure allows tools and materials of different sizes to be clearly categorized, preventing stacking or mixing. As a result, it helps:

Reduce retrieval time

Minimize damage risks

Improve overall workflow efficiency

That’s why more businesses choose Industrial Tool Cabinets over ordinary metal cabinets.

3. Corrosion-Resistant Surface Treatment for Demanding Conditions

Harsh industrial sites often involve:

Humid air

Chemical exposure

Oil contamination

High-quality industrial storage cabinets are typically finished with:

Electrostatic powder coating

Anti-rust treated steel

Industrial-grade surface processes

These treatments significantly extend cabinet lifespan, allowing reliable performance even in high-humidity or high-pollution environments.

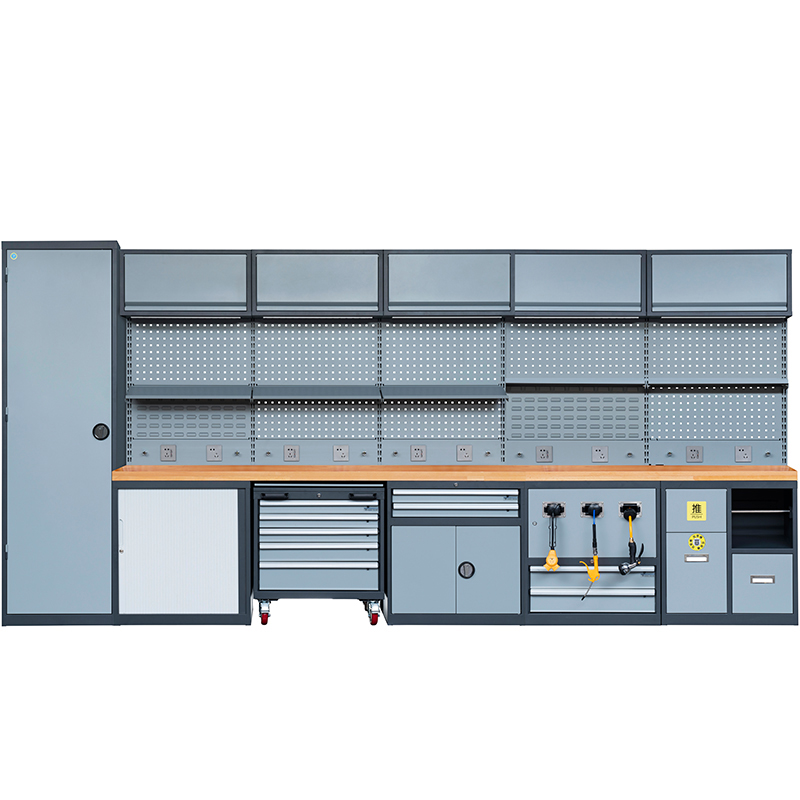

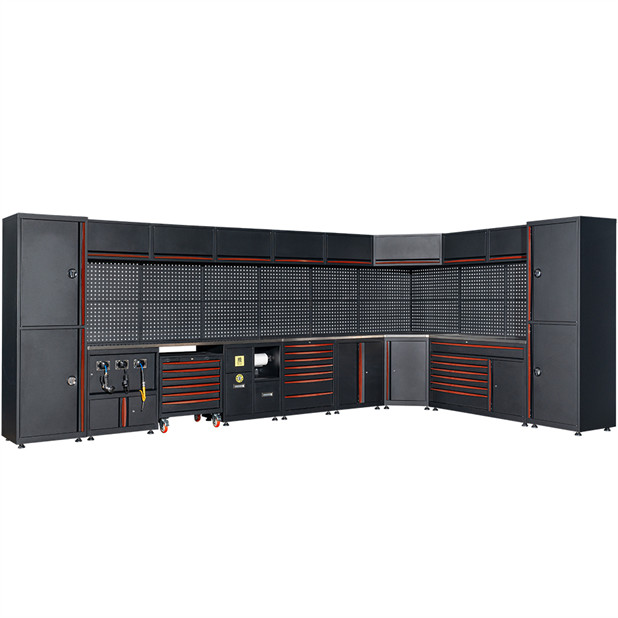

4. Modular Design to Fit Different Industrial Spaces

Modern industrial workspaces demand flexibility.

Many industrial storage systems now feature modular configurations, allowing cabinets to be freely combined based on site requirements. These modular solutions not only save space but also help build complete workstation systems, making them suitable for:

Production line maintenance areas

Equipment service stations

Automotive repair workshops

Warehouse technical zones

Such setups are often referred to as Industrial storage cabinet for harsh environments solutions.

5. Which Industries Benefit Most?

Industrial storage cabinets are widely used in:

Manufacturing plants

Automotive service centers

Industrial maintenance departments

Warehousing and logistics facilities

Technical service stations

Whether deployed as standalone cabinets or complete combination systems, they significantly improve on-site organization and operational efficiency.

Conclusion: Choose Storage Cabinets Truly Built for Industry

Harsh industrial environments place higher demands on storage equipment.

A reliable industrial storage cabinet is more than just a place to store tools—it plays a critical role in improving efficiency, enhancing safety, and optimizing workflows.

If your workspace involves heavy loads, frequent use, or complex operating conditions, we recommend choosing:

Heavy-duty steel construction

Multi-drawer classified storage

Industrial-grade surface treatment

Modular combination systems

Only these true Industrial Storage Cabinets can deliver long-term value in demanding environments.

Contact us today to receive tailored industrial storage cabinet solutions and complete workspace configurations for your projects.