When choosing durable storage cabinets for workshops, factories, and industrial environments, materials and structural design play a decisive role. A truly long-lasting cabinet is not defined by appearance alone—it must withstand heavy loads, frequent operation, vibration, and demanding working conditions.

So what materials and construction features make storage cabinets truly durable?

Let’s explore.

High-Quality Q235 Cold-Rolled Steel: The Foundation of Durability

Professional durable storage cabinets are typically built from Q235 cold-rolled steel, a widely used industrial-grade material known for its strength, formability, and long-term stability.

Compared with ordinary sheet metal, Q235 steel offers:

- Higher structural strength

- Better resistance to deformation

- Excellent weldability

- Consistent thickness and surface quality

This material provides a solid foundation for cabinets designed to carry heavy tools and equipment over many years of daily use.

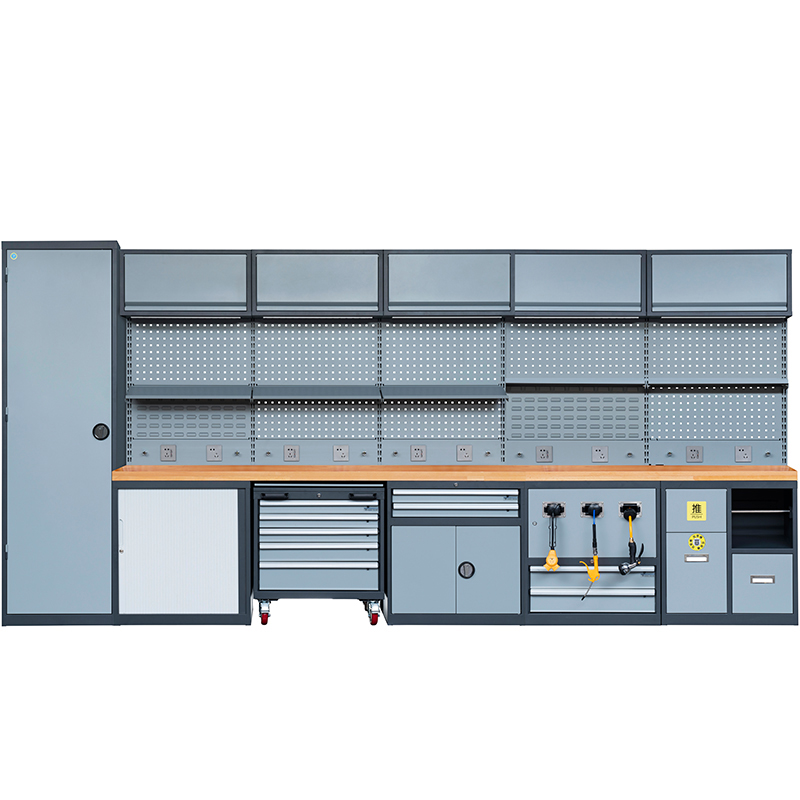

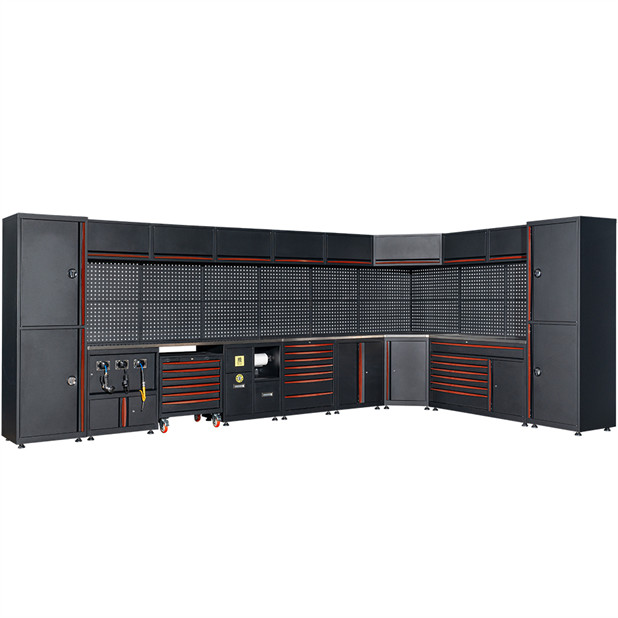

Reinforced Cabinet Structure for Heavy Loads

Material alone is not enough. Structural engineering determines real-world performance.

Industrial tool cabinets adopt internationally recognized cabinet structures featuring:

- Thickened internal load-bearing columns

- Reinforced cabinet frames

- Stable assembled construction

These design elements ensure strong load capacity and cabinet stability, even under continuous heavy-duty operation. This makes them ideal for storing:

- Heavy tools

- Industrial components

- Maintenance equipment

- Power tools and accessories

Such construction is essential for any durable storage cabinet used in professional environments.

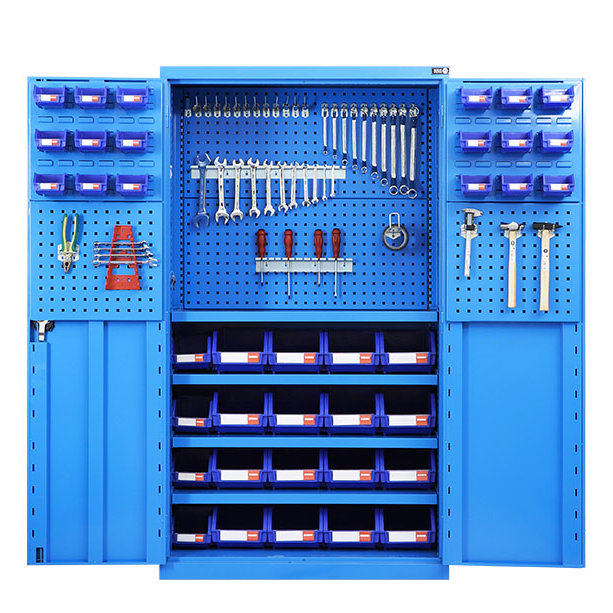

Central Locking System for Secure Tool Storage

Security is another key factor in durability-focused design.

Professional cabinets are equipped with a central locking system, allowing all drawers to be locked or unlocked with a single key. Each lock is supplied with two keys for backup.

This system helps:

- Prevent unauthorized access

- Protect valuable tools

- Improve daily management efficiency

Drawer Safety Mechanisms to Prevent Accidental Sliding

To ensure safe operation, drawers are fitted with automatic safety locking devices located beneath the handle. Without intentional user action, drawers will not slide out or fall, even when the cabinet is moved.

This feature significantly reduces workplace safety risks.

Integrated Handles and Label Holder Design

Each drawer handle is designed with end caps and an integrated plastic label holder.

- Flip-cover label slots allow easy replacement of identification tags

- Protective covers prevent labels from falling off or becoming damaged

- Fully enclosed ends improve user safety by eliminating sharp edges

These small details contribute to long-term usability and professional organization.

Single-Slide Drawer Rails with High Load Capacity

The drawer slide system is formed from 3 mm galvanized steel in a single stamping process, ensuring consistent quality and strength.

Key features include:

- Fixed positioning clips to prevent detachment during transport

- Four rolling bearings per slide for smooth operation

- 80–85% drawer extension

- Load capacity up to 100 kg per drawer

This makes the drawers suitable for heavy tools while maintaining smooth opening and closing.

Reinforced Cabinet Base for Mobility and Protection

The cabinet base protects the structure from ground impact and allows easy movement with pallet trucks or forklifts. Optional caster integration enables the cabinet to function as a mobile workstation.

Advanced Manufacturing Process Ensures Consistent Quality

Every durable storage cabinet goes through a complete industrial manufacturing workflow, including:

- CNC turret punching

- Laser cutting

- Press punching and shearing

- Bending and forming

- Spot welding and CO₂ shielded welding

- Acid pickling and phosphating

- Electrostatic powder coating

- Assembly and packaging

This controlled process ensures consistent structural quality, corrosion resistance, and professional surface finish.

Conclusion: Durable Storage Cabinets Start with the Right Materials

The best durable storage cabinets combine:

- Q235 cold-rolled steel construction

- Reinforced load-bearing structures

- Secure central locking systems

- Safety drawer mechanisms

- Heavy-duty slide rails

- Industrial-grade surface treatment

Together, these elements create storage solutions capable of performing reliably in demanding industrial environments.

If you’re looking for heavy-duty tool cabinets or durable storage systems built for professional use, choosing the right materials and engineering makes all the difference.

📩 Contact us today to learn more about our durable storage cabinet solutions and custom configurations.

.jpg)