In electronics manufacturing, semiconductor production, precision assembly, and laboratory environments, an ESD Workbench (Anti-Static Workbench) is a fundamental piece of equipment for protecting product quality and ensuring operator safety.

Electrostatic discharge (ESD) can damage sensitive electronic components in an instant. Therefore, a compliant and reliable ESD workbench must be systematically designed, structurally stable, and customizable to meet real production needs.

This article provides a comprehensive overview of the core specifications of an ESD workbench, covering design philosophy, structural standards, and material configurations.

1. Human-Centered Ergonomic Design

A high-quality anti-static workbench is not only about ESD protection but also about comfort and productivity:

Ergonomic height design reduces fatigue during long working hours

Well-proportioned tabletop space supports assembly, inspection, and repair tasks

Balanced structural design combines industrial aesthetics with practicality

Improves overall work efficiency and enhances the professional image of the workspace

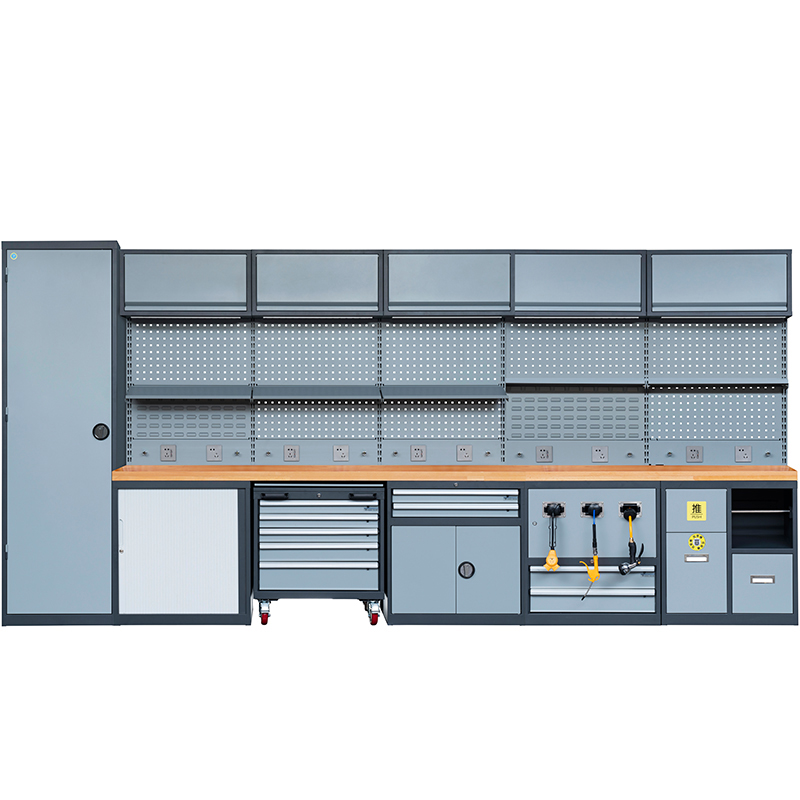

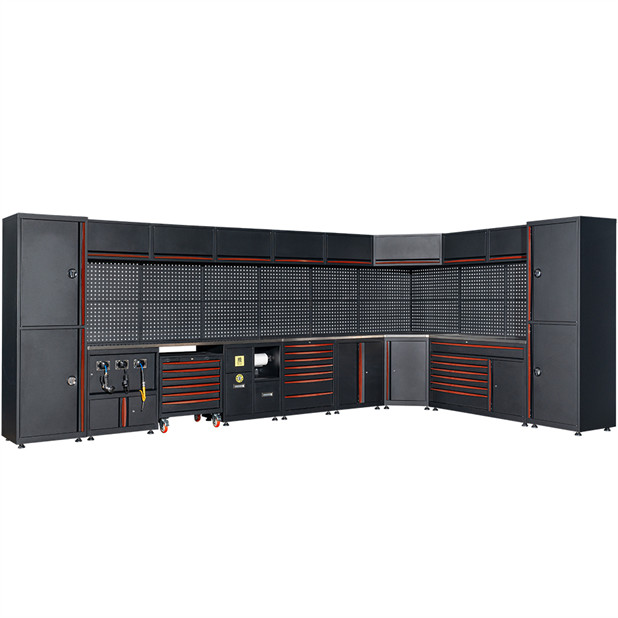

2. Modular Structure for Flexible Configuration

The ESD workbench adopts a modular design concept, allowing flexible combinations based on workstation requirements:

Multiple optional accessories: hanging panels, shelves, lighting systems, tool rails

Functional modules can be installed independently or combined freely

Easy to upgrade or expand in the future

Adapts to different production processes and workflow changes

With modularity, an anti-static workbench becomes a scalable work system rather than a fixed piece of equipment.

3. Standardized Design with Customization Capability

While meeting industry standards, ESD workbenches also support customization:

Standardized structures ensure stability and consistency for mass deployment

Size, load capacity, and configurations can be customized based on user needs

Suitable for different industries and workshop environments

Achieves a balance between standardized manufacturing and personalized application

4. Core Anti-Static and Material Specifications

4.1 Anti-Static Countertop

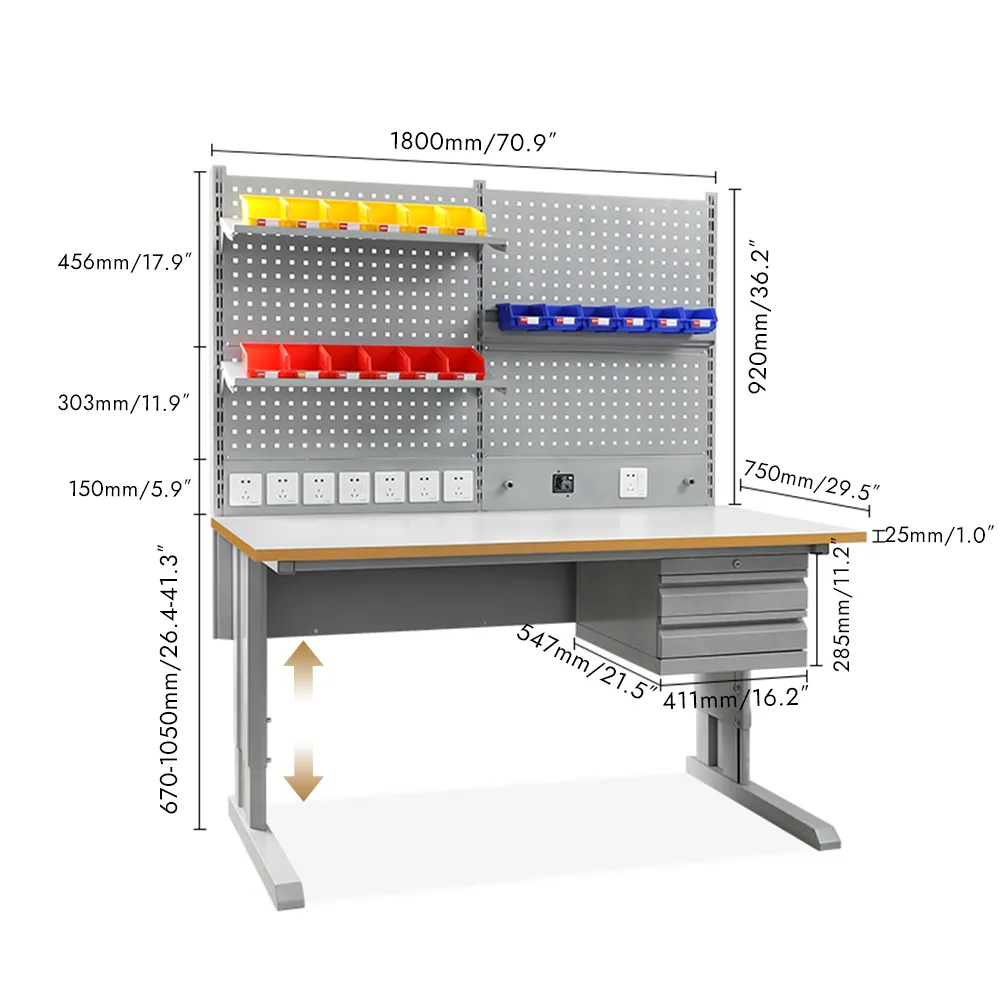

25mm German-imported anti-static tabletop

Overall ESD protection across the entire surface

Resistant to acids, alkalis, wear, oil, and impact

Effectively dissipates and directs static electricity to protect sensitive components

4.2 Metal Surface Treatment

All metal components undergo multiple industrial-grade surface treatments:

Pickling

Phosphating

High-voltage electrostatic powder coating

These processes ensure a smooth, durable, corrosion-resistant surface while extending service life.

4.3 Integrated Anti-Static System Design

An anti-static workbench is not just an ESD tabletop—it is a complete system:

Anti-static countertop

Grounded metal structure

Clearly defined static discharge paths

Eliminates static electricity risks at the source

This integrated design is ideal for environments with strict ESD control requirements

5. Functional Configuration Overview

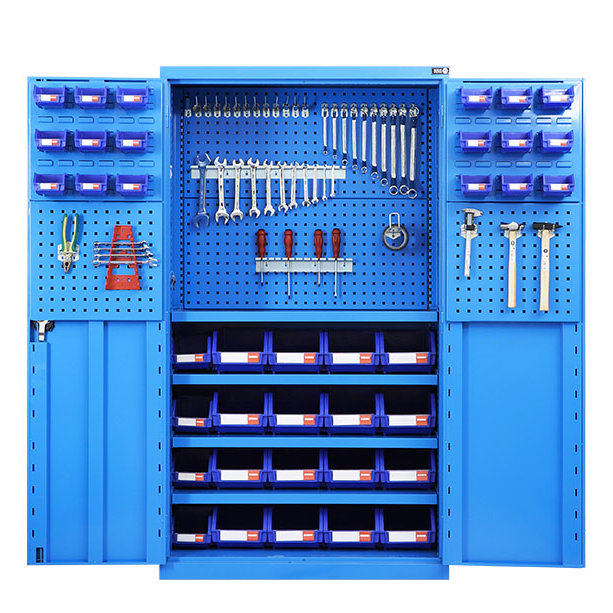

Hanging Panel System (Optional)

Pegboard / Louvered panel / Document hanging panel

Two standard sizes available, customization supported

Adjustable Tilted Shelf (Optional)

Height adjustable

15° tilt angle

20mm folded edge to prevent items from sliding

Lighting Panel and Rail System (Optional)

Adjustable height and front-back positioning

Optional light panel or tri-proof lamp (dustproof, waterproof, corrosion-resistant)

Compatible rail system

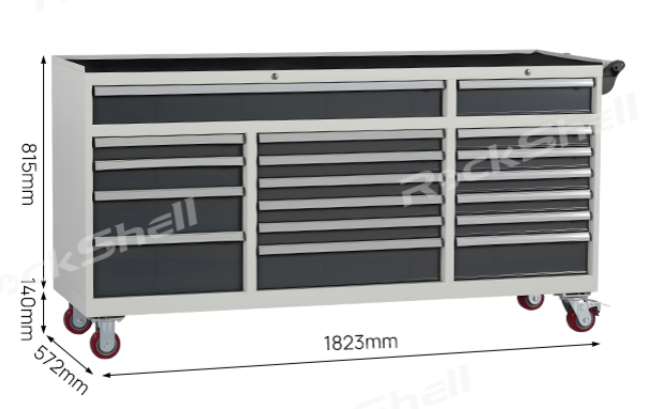

Two-Drawer Hanging Cabinet

Three-stage ball-bearing slides

45kg load capacity per drawer

100% full extension

50,000 open/close cycles

One-piece integrated handle panel

I-Beam Table Legs

Height adjustable by up to 350mm

Total load capacity up to 500kg

Exceptional stability for heavy-duty operations

Conclusion

What are the specifications for an ESD workbench?

The answer lies not only in numerical parameters, but in system-level design capability.

A professional anti-static workbench / ESD workbench should provide:

Stable and reliable ESD protection

Ergonomic and modular design

Industrial-grade materials and structural strength

Compatibility between standardized production and customization

In high-demand electronic and industrial environments, choosing the right ESD workbench is a critical step toward ensuring product quality, safety, and production efficiency.