Tool cabinets are essential for organizing tools in workshops and repair shops. They increase efficiency, protect valuable equipment, simplify workspace management and are a smart investment for professionals and hobbyists alike.

Why Choose a Tool Cabinet?

Storage Solution: A tool cabinet provides an efficient way to store tools while ensuring convenience and safety.

Protection: Protects tools from damage and theft, offering a secure storage solution.

Centralized Management: Enables centralized management of tools, simplifying the workspace and improving work efficiency.

What Types of Tool Cabinets Are There?

1.Portable Tool Cabinet

This type of tool storage solution is compact and easy to move. Although the storage capacity is limited, it is ideal for craftsmen, DIY enthusiasts, and professionals who need to transport their tools frequently.

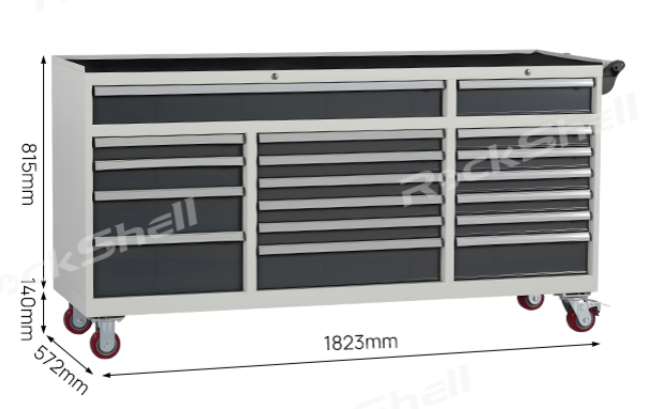

2.Rolling Tool Cabinets:

Also known as tool carts or rolling tool boxes, these cabinets are equipped with heavy-duty casters for easy mobility. They come in a wide range of sizes, from 2-3 drawers to multi-drawer configurations and hanging pegboards. Many models feature solid wood or stainless steel worktops, making them the preferred choice for mechanics, automotive technicians, and other professionals who require both a mobile tool storage and workspace solution.

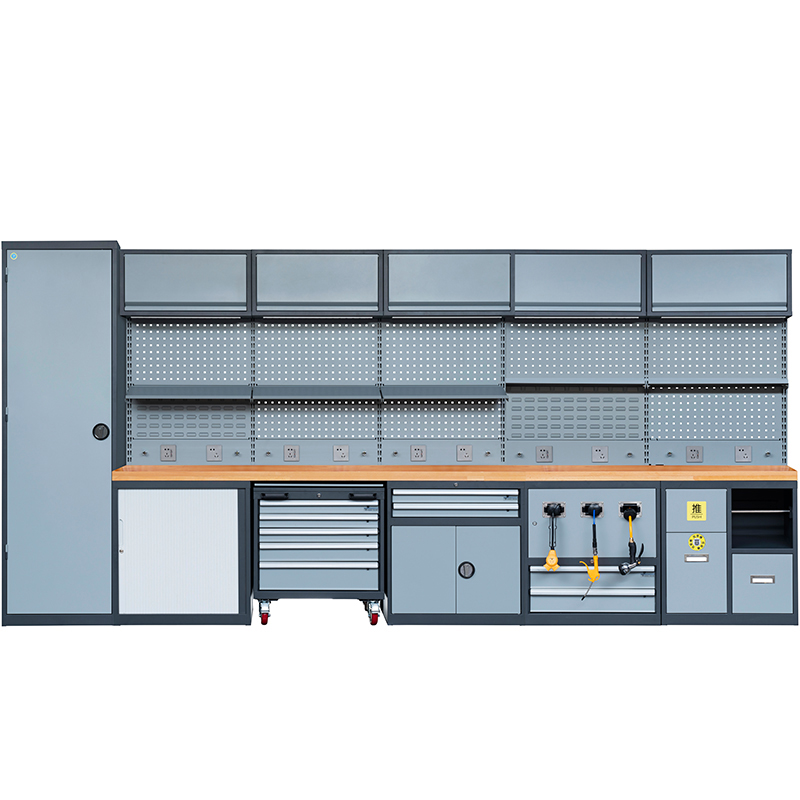

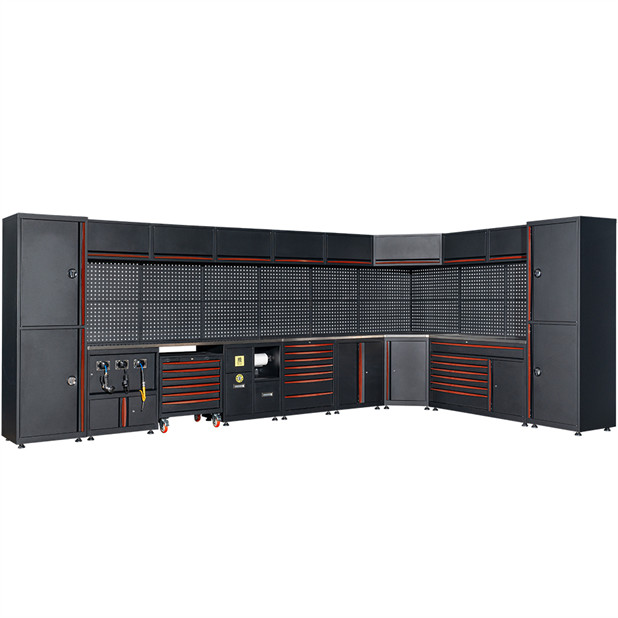

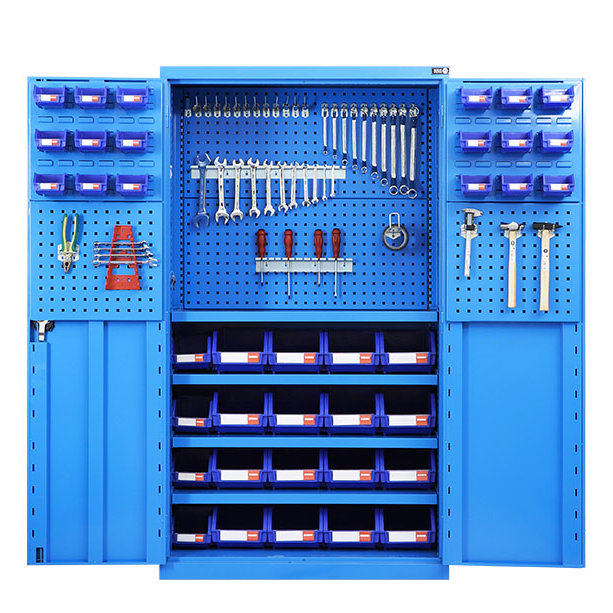

3.Stationary Tool Cabinets

These are typically floor-standing designs that are not easily moved but offer numerous customization options and flexible configurations. They provide superior durability and security, making them an excellent choice for fixed locations like workshops and garages. They are ideal for professionals and seasoned hobbyists who need long-term, secure storage for their tools.

How to Choose the Right Tool Cabinet?

1.Purpose and Use: Consider the primary purpose and use of the cabinet. Do you need a fixed or portable tool cabinet for your workshop or work environment? Defining your specific requirements will help you narrow down your options.

2.Size and Capacity: Size and capacity are critical when choosing a tool cabinet. The more drawers you have, the more organized your tools will be. Ensure the cabinet’s size can accommodate the number and types of tools you need to store. It’s advisable to choose a cabinet with slightly more capacity than you currently need, to allow space for future additions.

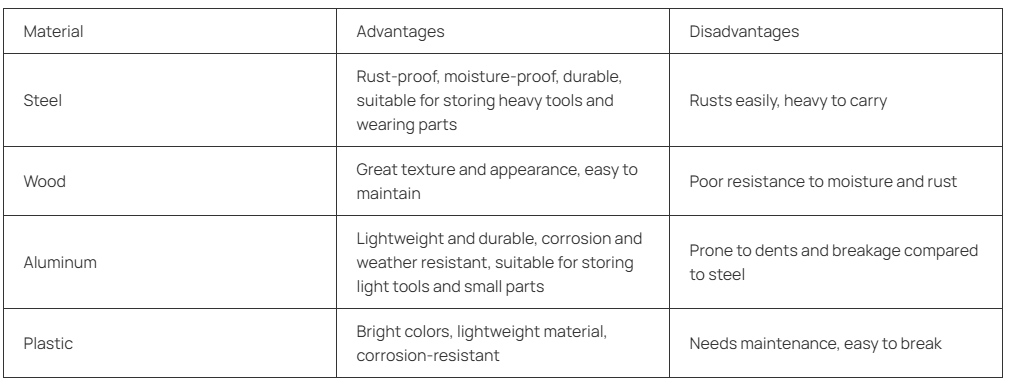

3.Material: Tool cabinets come in various materials, and your choice should depend on the environment in which it will be used. For example, in workshops, steel cabinets are commonly chosen due to their strength and wear resistance. Below, we will introduce four commonly used materials for tool cabinets.

4. Locking Mechanism:Most tool cabinets come equipped with a locking mechanism, which not only ensures the safe storage of your tools but also provides reliable security for your valuable equipment. You can choose the type of lock based on your needs. Common lock types include key locks, combination locks, and padlock compatibility.

5. Mobility and Additional Features: For scenarios that require frequent movement of tools, consider tool cabinets with wheels. Pay attention to the durability and smoothness of the wheels, and ergonomic handles, and whether the cabinet has a top platform to extend the operating space. These additional features can be tailored to meet your specific workflow needs.

6. Tool Organization :If tools need to be subdivided for classification and easy access, opt for tool cabinets with multiple compartments, dividers, and adjustable shelves. These features provide practicality and efficiency for quick organization and retrieval of tools.

7. Budget Considerations :Before purchasing a tool cabinet, it’s recommended to establish a clear budget. The price can vary depending on size, material, brand, and functionality. Make sure to choose a product that meets your quality and functionality requirements within your budget constraints.

8. Maintenance and Warranty :When selecting a tool cabinet, consider its maintenance and warranty options. Different materials require varying degrees of cleaning and maintenance. It’s advisable to check if the manufacturer offers a warranty to cover potential defects or damages.

How to Maintain a Tool Cabinet?

Regular Maintenance of Tool Cabinets:

1.Inspect for Damage: Periodically check the structure of the tool cabinet for any damage or wear.

2.Inventory Management: Regularly inventory the tools inside the cabinet. Replace damaged tools promptly, clean tools no longer in use, and add any new tools that need to be stored.

3.Tool Cleaning: After using tools, wipe off any grease, dirt, or residue before placing them back in the cabinet to prevent contamination and rust.

4.Cabinet Cleaning: Regularly clean the tool cabinet by emptying it and wiping down the surface with a soft cloth and cleaner to maintain its condition and functionality.

Rust Prevention Measures:

1.Control Humidity: Use moisture absorbers, such as silica gel, inside the tool cabinet to reduce humidity and inhibit rust and corrosion.

2.Dry Tools: Ensure that all tools are dry before placing them in the cabinet, and store the cabinet in a dry environment.

3.Rust Inhibitors: Apply rust inhibitors to tools and the cabinet when working in high-humidity environments. You can lubricate metal parts, refinish tool cabinets, or apply a thin layer of oil to both tools and the cabinet’s metal surfaces.

Tool cabinet development trend

1. Industry segmentation needs: for automotive maintenance, electronics manufacturing, electric power, and other industries to introduce special tool cabinets, such as anti-static cabinets, and anti-shock cabinets.

Modular design: support the flexible adjustment of drawer size, and partition layout, and even extend the cabinet combination, adapting to different spaces and types of tools.

2.Green and sustainable development

Application of environmentally friendly materials: adopting recyclable metals or low-carbon composite materials, responding to the policy of circular economy.

Energy-saving technology integration: Some smart cabinets are equipped with low-power sensors and temperature control systems to reduce energy waste.

3. Micro-market and Portability Innovation

Lightweight and multifunctional design: for home DIY users and small businesses, develop foldable, multifunctional storage boxes with mobile wheels that combine tool storage and workbench functions.

With this guide, you are well-informed to make your tool cabinet purchasing choices. Find the best tool storage solution for your workspace based on your unique needs, budget, and the factors we’ve highlighted.

FAQS

1. Material and structural design

Tool cabinets are mostly made of high-quality cold-rolled steel plates, and the surface is treated with an electrostatic plastic spraying process, which is both corrosion-resistant and wear-resistant. Part of the cabinet is equipped with polyurethane universal wheels, mobile and flexible, and does not damage the ground, drawer slides by 100,000 times pull test and is silent and load-bearing up to 50kg.

2. Convenient operation design focuses on humanization.

Removable hanging boards and categorized partitions. Part of the cabinet is equipped with safety clips to prevent the drawer from sliding down accidentally.

3. Safety and Maintenance

Tool cabinet with moisture-proof, dust-proof design to protect tool performance, while using independent locks or intelligent rights management to avoid unauthorized use. The environment inside the cabinet is dry and ventilated, and part of the cabinet supports a timeout reminding function to further reduce the management risk.

4. Multi-function and customization

Can be adapted to industrial tools, 3C electronics, fire equipment, and other categories of storage needs, drawer size, partition layout, and other support for customization to meet the personalized use of different scenes.

Compared with steel or aluminum, plastic and stainless steel tool boxes can adapt to humid environments, not easy to rust and corrosion.

Tool boxes are usually smaller and more portable. Larger, stationary tool cabinets have multiple drawers and compartments for more storage options.

The top of some tool cabinets can be used as a workbench. However, some tool cabinets are not suitable for this purpose. Therefore, it is necessary to check the product specifications in advance.

Most tool cabinets do not require assembly, so please check the product details in advance to determine if they are suitable for your preferences.