Which Is Better for Factory-Scale and Professional Use?

In automotive manufacturing plants, parts factories, and professional service workshops, a tool cabinet is no longer just a place to store tools. It has become a core component supporting large-scale operations, centralized maintenance, and standardized management.

When tool cabinets are deployed in large quantities across multiple workstations, choosing between a Professional Automotive Tool Cabinet and a Standard Workshop Cabinet directly impacts long-term efficiency, safety, and total operating cost.

Different Design Purposes: Professional vs General Use

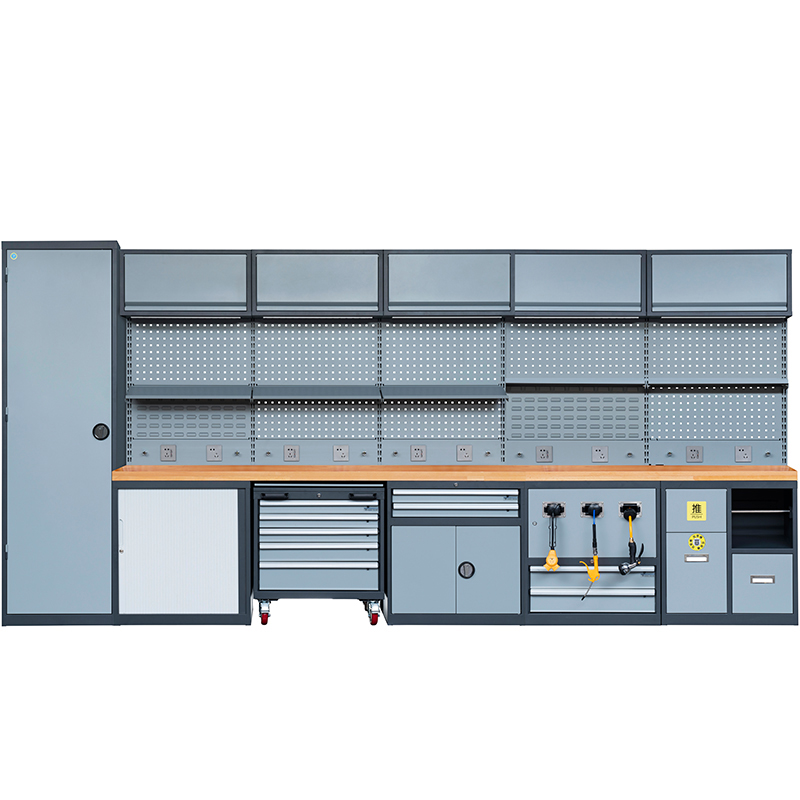

Professional Automotive Tool Cabinet

Designed specifically for automotive factories and industrial maintenance environments, it is built to support:

Multiple workstations operating simultaneously

High-frequency, long-hour usage

Large-scale, uniform deployment

Standardized workflows and repeatable layouts

Naturally suited for factory-level bulk purchasing and large-scale deployment.

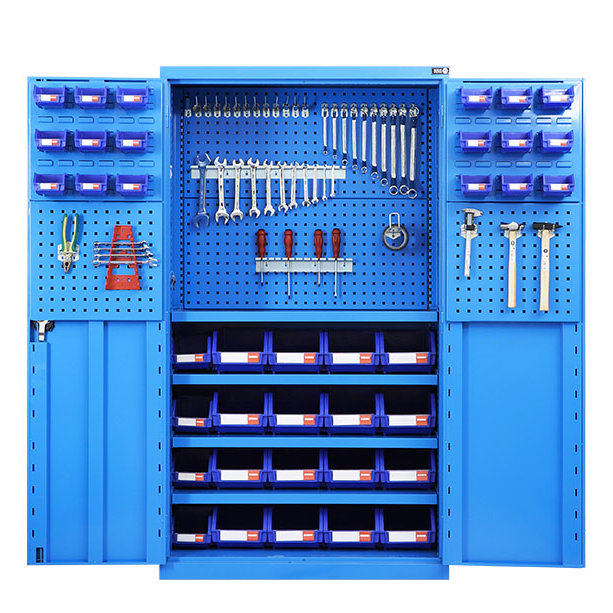

Standard Workshop Cabinet

Typically intended for:

Single workstations or individual users

Small workshops or light maintenance

Low to moderate usage intensity

When used at scale, standard workshop cabinets often reveal limitations in load capacity, durability, and consistency.

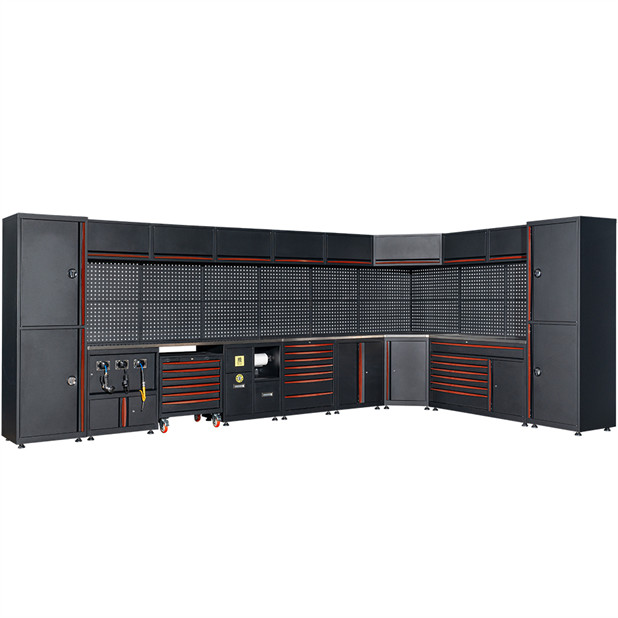

Cabinet Structure: The Foundation of Large-Scale Use

In factory environments, tool cabinets are expected to:

Be deployed in large quantities

Operate continuously over many years

Withstand intensive use by different operators

| Comparison Item | Professional Automotive Tool Cabinet | Standard Workshop Cabinet |

| Steel Thickness | Industrial-grade thick steel | Standard thin steel |

| Structural Design | Reinforced frame, anti-deformation | Basic structure |

| Stability in Bulk Use | High consistency | Inconsistent performance |

Large-scale use tests long-term structural stability and uniform quality.

Drawer Load Capacity: A Critical Factory Requirement

In factories, tools are often:

Heavier

Used more frequently

Shared among multiple technicians

Professional Automotive Tool Cabinets feature:

Heavy-duty drawer slide systems

Higher single-drawer load ratings

Smooth operation even under long-term full load

Standard Workshop Cabinets, when deployed in large numbers, are more likely to experience:

Drawer sagging

Accelerated slide wear

Performance variation between units

Safety Design: Essential for Large-Scale Deployment

When tool cabinets are used in large quantities, safety risks multiply.

Professional Automotive Tool Cabinets typically include:

Centralized drawer locking systems

Anti-accidental-opening designs

Optimized weight distribution to reduce tipping risk

These features are essential in multi-shift, multi-operator factory environments.

Mobility and Casters: Reliability Under Heavy, Repeated Use

In factory settings, tool cabinets often need to:

Move frequently while fully loaded

Operate on various floor conditions

Withstand long-term heavy loads

Professional Automotive Tool Cabinets are equipped with:

Heavy-duty casters designed for industrial use

Braked swivel wheels for operational stability

Cabinet structures engineered to match caster load capacity

Standard Workshop Cabinets are better suited for light-duty or limited-quantity use.

Space Management and Standardization

Professional Automotive Tool Cabinets are designed for:

Uniform dimensions and configurations

Standardized drawer layouts

Customizable internal dividers based on factory needs

This makes them ideal for large-scale procurement, deployment, and long-term management in factories.

Which Cabinet Is Better for Factory-Scale Use?

Choose a Professional Automotive Tool Cabinet if you:

Operate multiple maintenance or production workstations

Require bulk purchasing with consistent specifications

Manage growing tool inventories

Prioritize long-term stability and safety

Choose a Standard Workshop Cabinet if you:

Run a small or individual workshop

Have low usage frequency

Do not require standardized deployment

Conclusion: Factory-Level Operations Require Professional-Grade Tool Cabinets

In the comparison between Professional Automotive Tool Cabinet vs Standard Workshop Cabinet, the key factor for factories is not the unit price, but:

Suitability for large-scale deployment

Long-term performance consistency

Reduced maintenance and replacement costs

Professional Automotive Tool Cabinets are engineered specifically for factory-level, large-scale use.

Choosing professional-grade storage is essential to supporting the long-term efficiency and reliability of automotive manufacturing and industrial maintenance systems.