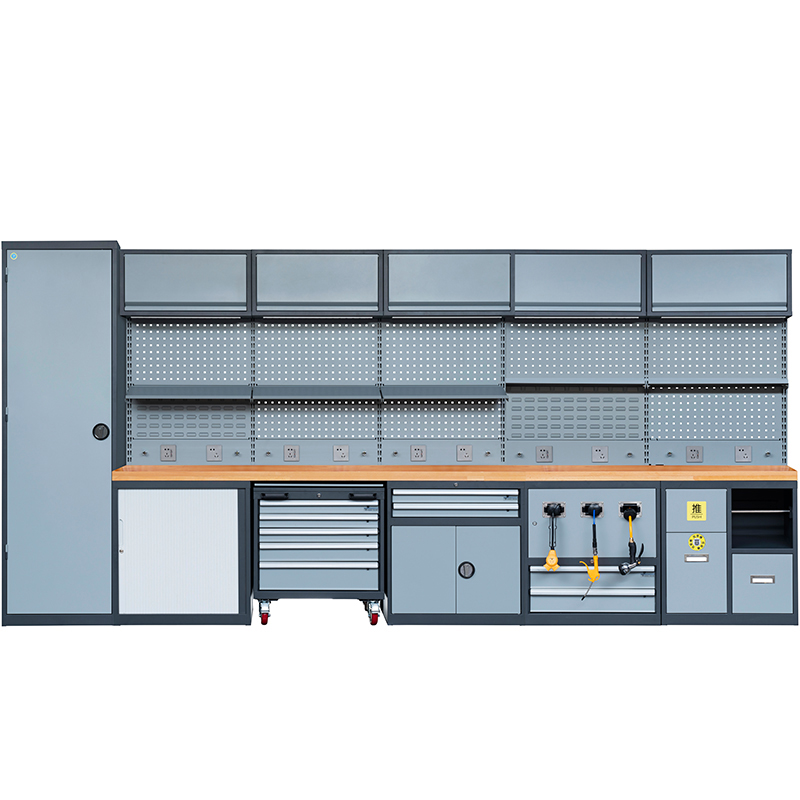

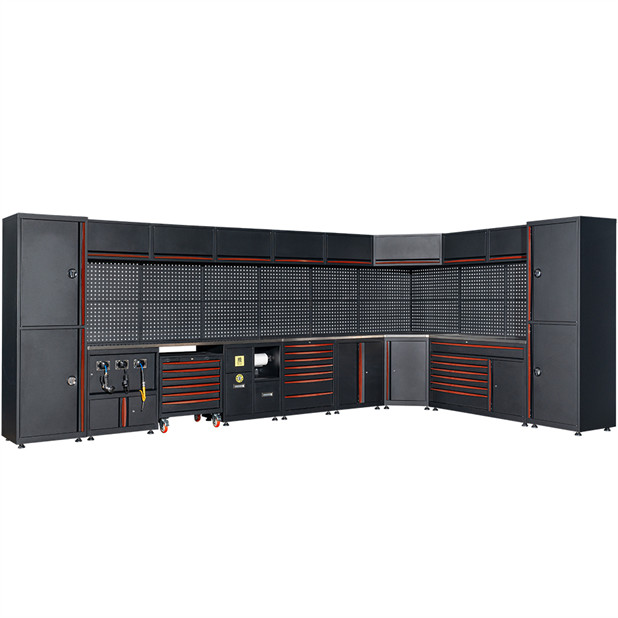

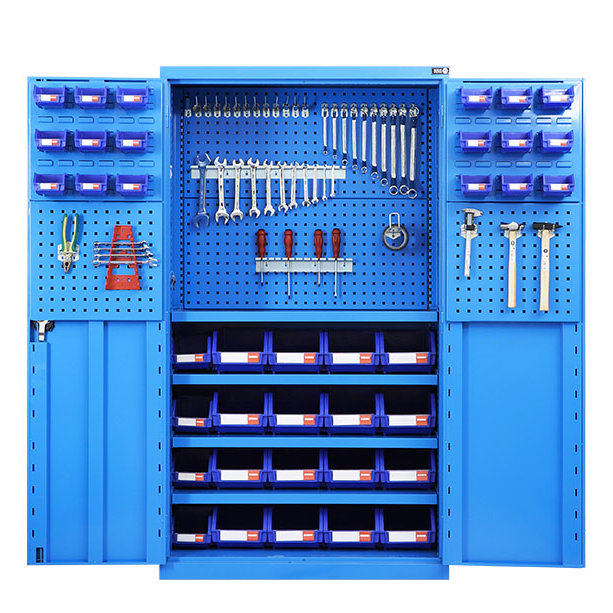

Range of sizes 8 standard colors

※ All custom RAL available

Bespoke service for over-sized cabinets

Can be fully personalised

Safe, neat and orderly storage

Long-Lasting Warranty

PRODUCT INFORMATION

This CNC tool cart adopts a differentiated drawer slide design to meet the storage and access requirements of different tools: the first drawer at the top uses heavy-duty single-track slides that can be pulled out 85% to facilitate quick positioning of frequently used tools; the two drawers at the bottom are equipped with high-strength heavy-duty double-track slides that support 100% full pull-out and can be easily operated even when storing long or heavy tools.

The total tool holder capacity of the tool cart is 34 BT50 tool holders: 16 BT50 tool holders are integrated into the top work surface, which is convenient for machine tool operators to temporarily store and replace tools; two sturdy bridge-type handles are installed in front of the body for easy movement around the shop. Four high-quality 4-inch casters are installed on the bottom, two of which are fixed wheels. The other two are universal wheels with brake functions to ensure directional control during movement and stationary stability. The surface of the body is subjected to strict pickling and phosphating pretreatment. Then environmentally friendly electrostatic powder spraying is applied to form a strong, wear-resistant, and rustproof protective layer.

PRODUCT SPECIFICATIONS

BT50- GM Series CNC Tool Trolley

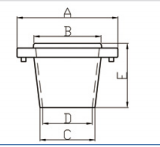

| Model No. | Size(mm) | Pictures of Knife Sleeves | A | B | C | D | E | Load capacity | N.W./G.W. | CBM |

| BT50-G34 | W565*D572*H1291 |

| 108 | 72 | 59 | 53 | 69 | 1000KG | 70KG/71KG | 0.50 |

PRODUCT FEATURES

CNC tool drawer

Drawers over 350mm come standard with standard CNC tool trays, the drawers are sealed and dust-proof, keeping stored items clean and tidy at all times.

Heavy duty double rail

Double rail supports up to 150kg per drawer, with 100% full extension capability.

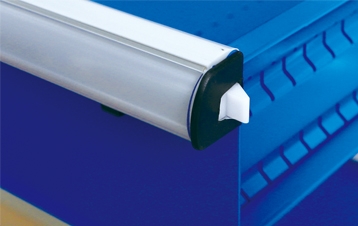

Safety buckle

The self-locking system is strong and reliable and will not fall off automatically without human intervention, making it safer to use. The handle is equipped with a transparent protective cover, which makes it easy to check the labeling information.

Top CNC tool tray

Easy access and improved user experience with an open-top CNC tool tray.

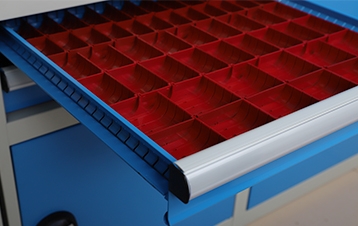

Drawer sorting slots

The upper drawer adopts a partition design, which is made of ABS material in one step. It has the characteristics of acid, alkali, and oil resistance, which is convenient for the classification and storage of various tools and parts.

REGARDING PRODUCT FAQS

First, accurately assess the number of tool holders you need and estimate the maximum weight you will need to support to ensure the trolley can meet your storage needs. Second, choose the appropriate caster material and size based on the frequency of use of the tool cart and the floor conditions of the workplace. High-quality casters are essential for tool carts that are moved frequently. Next, consider whether you need a tabletop with non-slip mats or special features that will directly affect comfort and efficiency. Finally, within your budget, fully evaluate the overall structure, materials, and user reports of the tool cart and choose a durable and reliable product to ensure long-term value.

After receiving your deposit, we usually need 5-10 days for 20GP container and 20-25 days for 40HQ.

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we can regard your inquiry priority.