In modern industrial workshops, manufacturing plants, and professional maintenance environments, the industrial rolling tool cabinet has become an essential solution for improving workflow efficiency and tool management. Compared with stationary tool cabinets, industrial rolling tool cabinets offer greater mobility, convenient access, and adaptability across multiple work areas.

However, different specifications, structures, and configurations can lead to significant differences in performance and user experience. This guide outlines key selection criteria to help businesses make informed and practical decisions when purchasing an industrial rolling tool cabinet.

1. Focus on Load Capacity and Drawer Structure

When selecting an industrial rolling tool cabinet, the drawer slide configuration directly determines load capacity, operating smoothness, and overall usability. Different tools and equipment require different load ratings and extension options, which is why industrial-grade tool cabinets typically support multiple slide configurations.

Single Slide Drawer

Single slide drawers are designed for standard industrial storage needs, balancing strength and smooth operation:

Load capacity: Up to 100 kg per drawer

Extension: 85% smooth extension

Ideal for hand tools, pneumatic tools, and standard industrial components

Stable structure and cost-effective for most workshop applications

Double Slide Drawer

For heavy-duty tools or high-frequency access, double slide drawer designs provide higher load capacity and full accessibility:

Load capacity: Up to 150 kg per drawer

Extension: 100% full extension

Suitable for heavy power tools, molds, and large equipment

Maintains stable and smooth operation even under full load

Flexible Configuration for Diverse Needs

High-quality industrial rolling tool cabinets allow free combination of single and double slide drawers. Users can configure drawers based on tool weight and usage frequency:

Single slide drawers for light to medium tools

Double slide drawers for heavy or bulky tools

This flexible configuration improves space utilization and allows the cabinet to adapt to future tool storage requirements.

2. Caster Quality Determines Mobility and Safety

Casters are a critical component of any industrial rolling tool cabinet, directly affecting mobility and operational safety.

Key factors to consider include:

Caster material (polyurethane, rubber, etc.)

Load capacity per caster

Availability of braking mechanisms

High-quality industrial rolling tool cabinets typically feature heavy-duty industrial casters, with at least two locking casters to ensure stability during use.

3. Locking Systems and Safety Features

In industrial environments, both tool security and operator safety are essential.

Recommended safety features include:

Central locking systems for all drawers

Drawer interlock mechanisms to prevent multiple drawers from opening simultaneously

Anti-tip designs for enhanced stability

These features protect valuable tools while reducing the risk of workplace accidents.

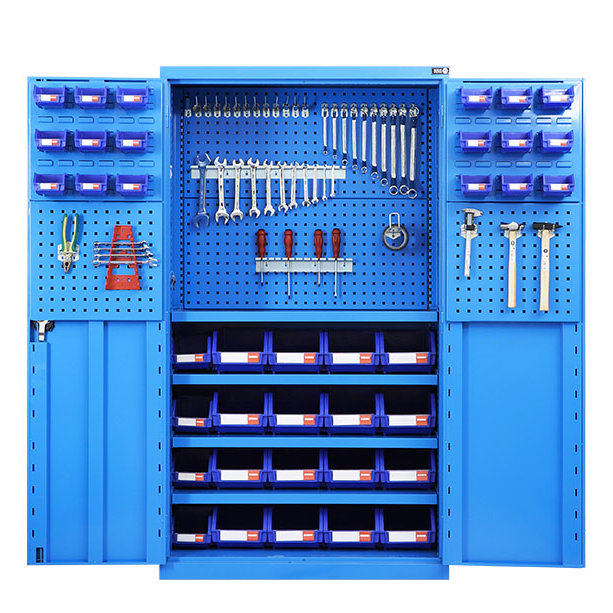

4. Drawer Layout and Internal Accessories

A well-designed internal layout significantly improves tool organization efficiency.

When selecting an industrial rolling tool cabinet, consider:

Drawers with varied height combinations

Adjustable dividers and compartment boxes

Label frames or identification systems

Modular drawer designs allow businesses to adjust storage layouts as tool inventories evolve.

5. Material and Surface Treatment

Industrial environments demand high durability.

A premium industrial rolling tool cabinet typically features:

Cold-rolled steel or high-strength steel construction

Powder-coated or industrial-grade surface finishes

These treatments provide resistance to oil, moisture, and chemical exposure, extending service life.

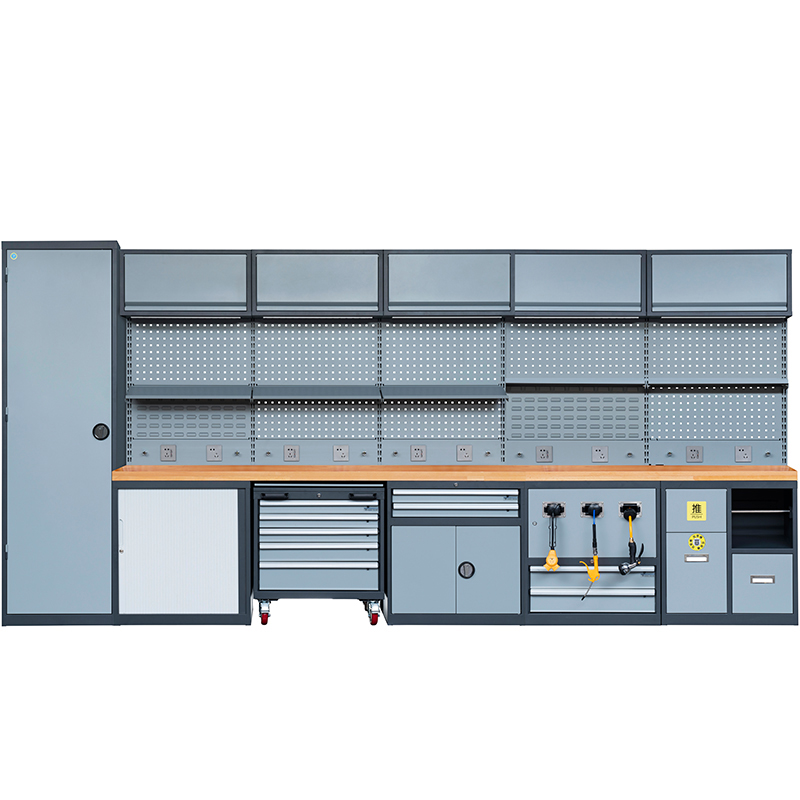

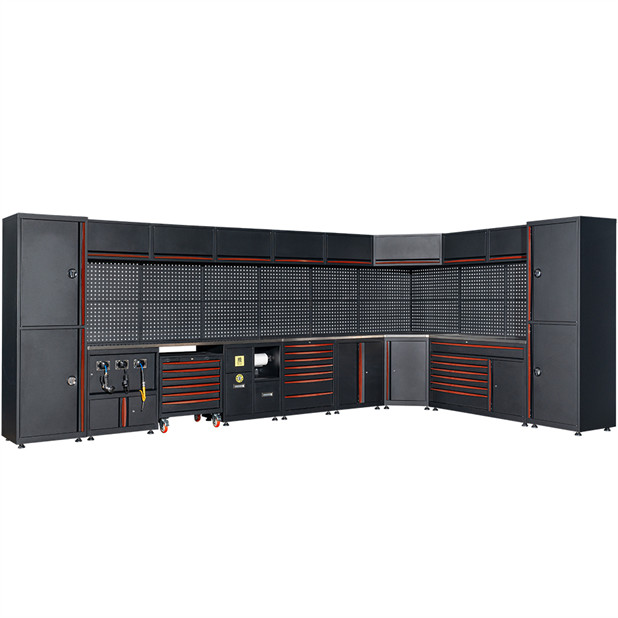

6. Customization and Expansion Options

Standard products may not fully meet enterprise-level requirements.

Many manufacturers offer OEM / ODM industrial rolling tool cabinet services, including:

Custom dimensions and drawer configurations

Adjustable load ratings

Custom colors and branding

Customization support ensures long-term scalability and brand consistency.

Conclusion: Selecting the Right Industrial Rolling Tool Cabinet

Choosing the right industrial rolling tool cabinet requires a comprehensive evaluation of load capacity, mobility safety, internal structure, durability, and future expansion needs.

For high-intensity and high-frequency operations, prioritizing heavy-duty construction, premium casters, and comprehensive safety systems ensures long-term efficiency and reduced maintenance costs.