Tool carts play a critical role in garages, maintenance workshops, and industrial environments. However, when choosing the right solution, many buyers face the same question:

What is the difference between a heavy duty tool cart and a standard tool cart—and which one should I choose?

This guide compares heavy duty and standard tool carts from the perspectives of load capacity, construction, storage efficiency, and long-term value, helping you select the best option for your application.

1. What Is a Heavy Duty Tool Cart?

A heavy duty tool cart is designed for professional and industrial use where tools are heavy, usage is frequent, and durability is essential.

Key characteristics include:

Thicker steel cabinet construction

High drawer load capacity

Reinforced ball bearing slides

Industrial-grade casters

Designed for long-term, full-load operation

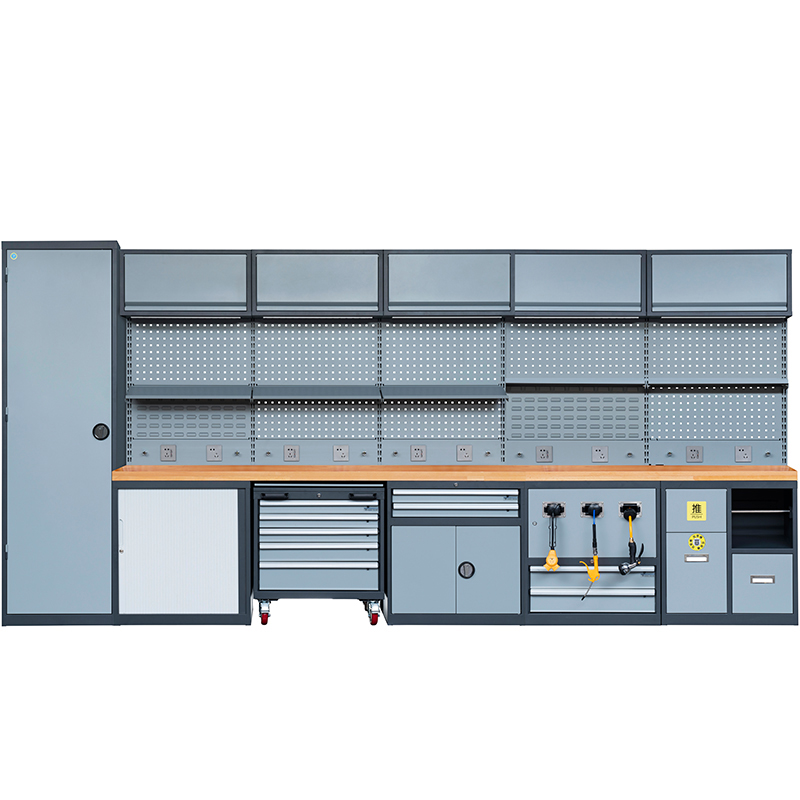

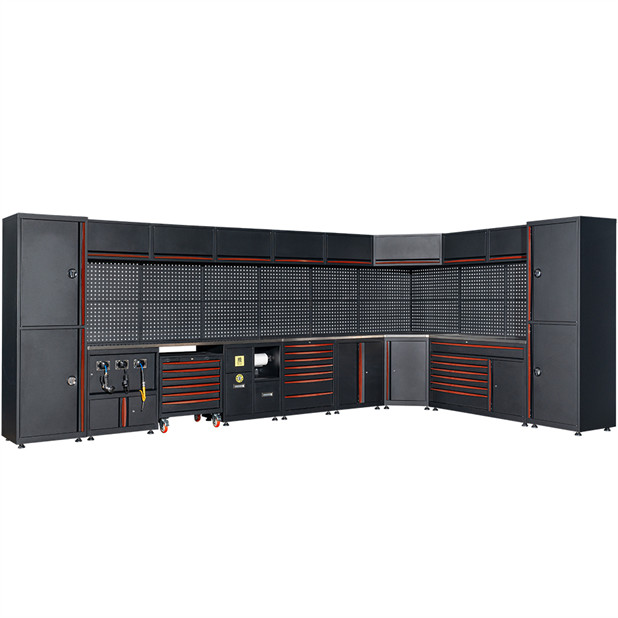

Heavy duty tool carts are commonly used in industrial workshops, service bays, production facilities, and professional garages.

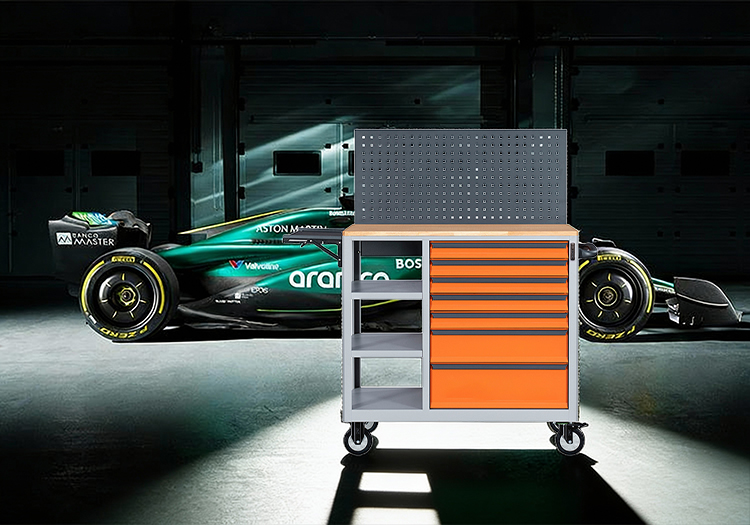

2. What Is a Standard Tool Cart?

A standard tool cart focuses on practicality and cost-efficiency, making it ideal for:

Home garages

Light-to-medium maintenance work

Automotive repair shops with moderate tool weight

Standard models still offer reliable performance but are optimized for general tool storage rather than extreme loads.

3. Drawer Load Capacity: The Key Difference

Drawer Load Comparison

| Tool Cart Type | Single Drawer Load Capacity |

| Heavy Duty Tool Cart | 100–150 kg per drawer |

| Standard Tool Cart | 30–45 kg per drawer |

A typical standard tool cart uses three-section ball bearing slides with:

45 kg drawer load capacity

100% full-extension design

Heavy duty tool carts use reinforced or dual-slide systems, allowing safe storage of power tools, impact wrenches, and heavy components without drawer deformation.

4. Cabinet Structure and Material Thickness

Steel thickness directly affects stability and durability.

Heavy duty tool carts: thicker steel (typically ≥1.0 mm)

Standard tool carts: approx. 0.8 mm thick steel

Thicker steel improves:

Resistance to bending under load

Cabinet rigidity when fully loaded

Long-term durability in industrial environments

5. Slide System and Service Life

Standard Tool Cart Slides

Three-section ball bearing slides

100% drawer extension

Tested for 50,000 open-close cycles

Smooth operation for daily use

Heavy Duty Tool Cart Slides

Reinforced or double-slide systems

Stable performance under heavy loads

Lower failure rate over long-term use

For high-frequency, high-load operations, heavy duty slides provide better long-term reliability.

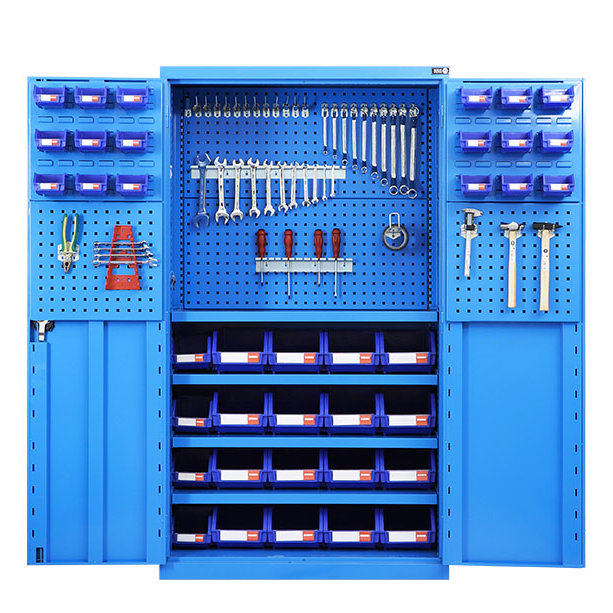

6. Internal Storage Efficiency

Both heavy duty and standard tool carts benefit from well-designed drawer organization systems.

Standard Tool Cart Storage

Pre-formed divider slots

Optional front-to-back adjustable dividers

Ideal for hand tools such as wrenches and screwdrivers

Heavy Duty Tool Cart Storage

Deeper drawers

Higher density storage for heavy tools

Designed for centralized management of industrial equipment

Proper drawer organization significantly improves space utilization and workflow efficiency.

7. Casters and Overall Load Capacity

Standard Tool Cart

Ø125 mm silent casters

2 swivel casters with brakes + 2 fixed casters

Single caster load capacity: approx. 160 kg

Total cart load capacity: up to 500 kg

Heavy Duty Tool Cart

Industrial-grade heavy-load casters

Better impact resistance

Suitable for uneven floors and frequent movement

8. Application Scenarios

Choose a Heavy Duty Tool Cart If You:

Store heavy or power tools

Operate in industrial or production environments

Require high load capacity and long service life

Prioritize safety and structural stability

Choose a Standard Tool Cart If You:

Use light to medium-weight tools

Work in a garage or general repair shop

Need cost-effective and flexible storage

Focus on daily maintenance tasks

Conclusion: The Right Tool Cart Is the One That Fits Your Workload

The main difference between a heavy duty tool cart and a standard tool cart lies in load capacity, structural strength, and long-term durability.

Heavy duty tool carts are a smart investment for demanding environments with heavy tools and frequent use.

Standard tool carts, when well-designed, offer excellent efficiency and value for everyday workshop needs.

Choosing the right tool cart means investing in productivity, safety, and long-term performance.