In global manufacturing, maintenance workshops, and industrial service scenarios, a Tool Cart is an essential solution for improving operational efficiency and tool management. Depending on load capacity and usage intensity, tool carts are generally categorized into Industrial Tool Cabinets and Workshop Storage Carts.

This article provides a detailed comparison of the Global Industrial Tool Cabinet (single drawer load >100kg) and the Workshop Storage Cart (single drawer load >45kg), helping users make an informed choice based on their specific applications.

1. Core Positioning Differences

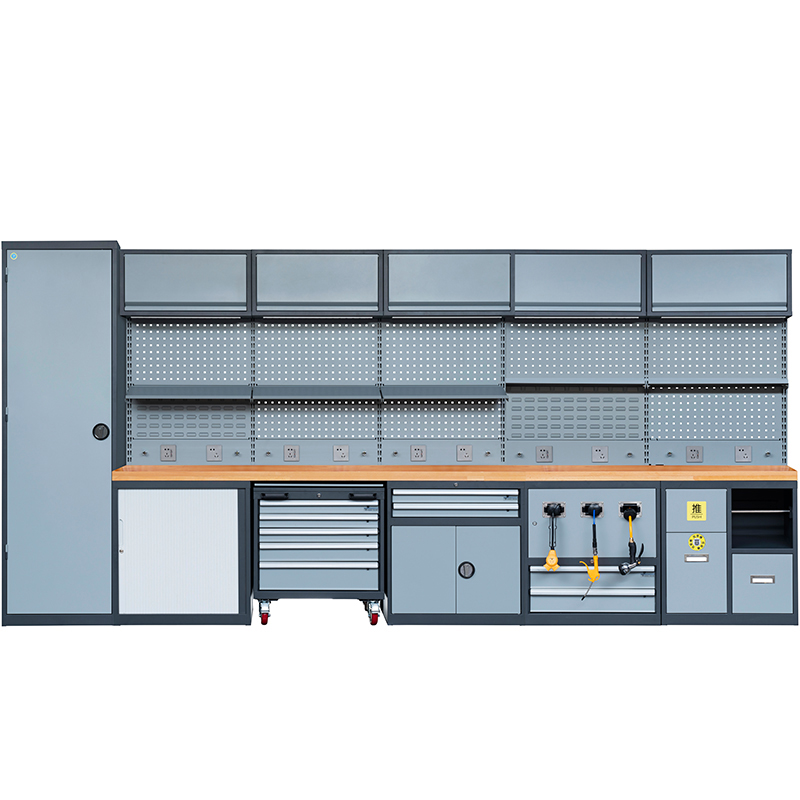

Industrial Tool Cabinet

- Single drawer load: ≥100kg (up to 150kg in some configurations)

- Ideal for heavy manufacturing, equipment maintenance, and mold management in high-intensity industrial environments

- Emphasizes maximum load capacity, safety, and long-term durability

Workshop Storage Cart

- Single drawer load: ≥45kg

- Suitable for daily maintenance, assembly workshops, light industry, and general service scenarios

- Focuses on flexibility, cost-effectiveness, and high-frequency usability

2. Cabinet Structure and Material Comparison

Both products use thickened steel construction to ensure stability and durability:

- Steel thickness: ≥0.8mm

- Cold-rolled steel, rigid structure, resistant to deformation

- Suitable for long-term industrial use

The Industrial Tool Cabinet further strengthens the overall structure and load-bearing design, making it ideal for storing heavy tools and equipment.

3. Drawer Slides and Load Capacity

Workshop Storage Cart (KX-1027X Series)

- Three-section ball-bearing slides

- Single drawer load: 45kg

- 100% full-extension

- 50,000 open/close cycles lifespan

- Smooth operation, suitable for high-frequency use

Example configuration (KX-1027X Series):

- 7 drawers

- φ125mm silent casters

- Total load capacity up to 500kg

Industrial Tool Cabinet (T1023 Series)

- Free configuration of slide rails according to tool weight and usage needs

Single Slide Drawer

- Single drawer load: 100kg

- Drawer extension: 85%

- Suitable for standard industrial tool storage

Double Slide Drawer

- Single drawer load: up to 150kg

- 100% full-extension

- Ideal for heavy tools, molds, and large equipment

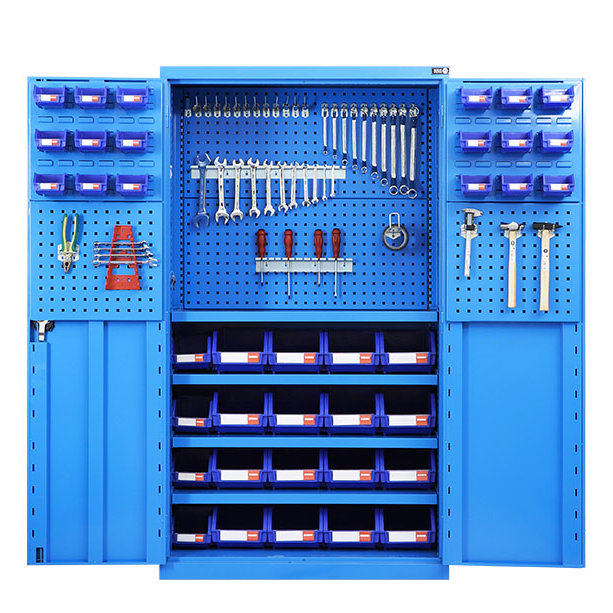

4. Drawer Internal Organization

Both products support highly flexible drawer organization solutions:

- Adjustable drawer dividers

- Pre-drilled divider slots

- Support for 3×3, 3×4, 3×5 combinations

- ABS molded storage bins

- Divider and partition systems

Proper organization allows each drawer to store a specific type of tool or component, significantly improving work efficiency.

5. Safety Locking Systems

Standard and optional safety features:

- Central locking system: one lock controls all drawers, with 2 keys per lock

- Self-locking drawers prevent accidental slide-out

- Interlock system (optional, Industrial Tool Cabinet): only one drawer can open at a time, preventing tipping and enhancing safety

The Industrial Tool Cabinet offers higher safety levels and anti-tip designs suitable for high-risk industrial environments.

6. Top Work Surface Options

Workshop Storage Cart

- ABS worktop: wear-resistant, non-slip, easy to clean

- Equipped with ABS protective edges

Industrial Tool Cabinet (multiple options)

- Steel worktop with rubber mat

- Beechwood solid wood worktop

- Cold-rolled steel worktop

- Flexible selection based on maintenance, assembly, or heavy-duty requirements

7. How to Choose the Right Tool Cart

Choose an Industrial Tool Cabinet if you:

- Need to store heavy tools, molds, or equipment

- Require high single-drawer load capacity and safety

- Work in high-intensity industrial environments

Choose a Workshop Storage Cart if you:

- Primarily store standard maintenance or assembly tools

- Value cost-effectiveness and mobility

- Operate in workshop, maintenance, or light industrial scenarios

Conclusion

The Global Industrial Tool Cabinet and Workshop Storage Cart are not competitors but professional solutions tailored for different applications.

- Industrial cabinets emphasize maximum load capacity, safety, and long-term stability

- Workshop carts focus on flexibility, efficiency, and value

Choosing the right configuration based on actual working conditions ensures maximum tool management efficiency and return on investment.