An anti-static workbench protects sensitive electronics from electrostatic discharge by safely dissipating static electricity. Essential in electronics, medical, and aerospace industries, it ensures equipment safety, boosts efficiency, and provides a secure working environment.

What is an Anti-Static Workbench?

An anti-static workbench is a workstation designed to eliminate static electricity and protect sensitive electronic components from the harmful effects of electrostatic discharge (ESD). It uses grounded surfaces and anti-static materials to ensure the safety of the equipment.

The Working Principle of an Anti-Static Workbench

The main purpose of an anti-static workbench is to conduct static electricity to the ground, thus reducing the risks associated with static buildup. Traditionally, static-dissipative workbenches are used. Initially, conductive surfaces like stainless steel countertops were employed, but they can lead to short circuits and cause high currents that pose safety risks when grounding issues arise. Therefore, for safety reasons, it’s essential to use high-resistance dissipative surfaces. The countertop resistance should range between 1.0 x 10^6 to 1.0 x 10^9 ohms, allowing static charges to dissipate safely and quickly.

Types of Anti-static Countertops:

ESD Rubber Desk Pad: This is a common anti-static material, which is soft and offers a certain degree of cushioning when placing items. The price is economical, but it has drawbacks such as poor abrasion resistance, aging over time, and a shorter service life. Poor-quality rubber pads may emit a pungent odor, and the surface can be damaged during welding work.

Anti-static Laminated Tabletop (Fireproof): These tops are more expensive but offer superior wear resistance and high-temperature tolerance, making them a popular choice for many users.

The Role of an Anti-static Workbench

Prevent Static Damage: Anti-static workbenches utilize conductive materials and grounding systems to prevent static electricity generation and accumulation, thereby protecting electronic components. This improves product quality and reliability.

Enhance Production Efficiency: By minimizing interruptions and rework caused by static electricity, an anti-static workbench reduces scrap rates, shortens production cycles, and ultimately boosts overall production efficiency.

Safeguard Personnel Safety: Anti-static workbenches help protect employees from electric shock injuries by providing a secure environment free from hazardous static buildup.

Applications of Anti-Static Workbenches

Electronic Manufacturing: In the production of electronic components, static electricity can damage devices, integrated circuits, and other sensitive equipment. Using anti-static workbenches effectively reduces the generation of static electricity, preventing damage and ensuring product quality and reliability.

Medical Equipment: Many medical devices require a precise operating environment. Static electricity or electromagnetic interference can cause errors and malfunctions. Anti-static workbenches ensure that medical equipment functions optimally and extends its lifespan.

Laboratories: In scientific research and experiments, static electricity can disrupt precision instruments and compromise the accuracy of results. Anti-static workbenches provide a stable, static-free environment for such work.

Aerospace and Communications Equipment Manufacturing: In these high-tech fields, the need for electrostatic protection is critical. Anti-static workbenches help ensure the safety of sensitive electronic components, preventing electrostatic discharge from damaging critical equipment.

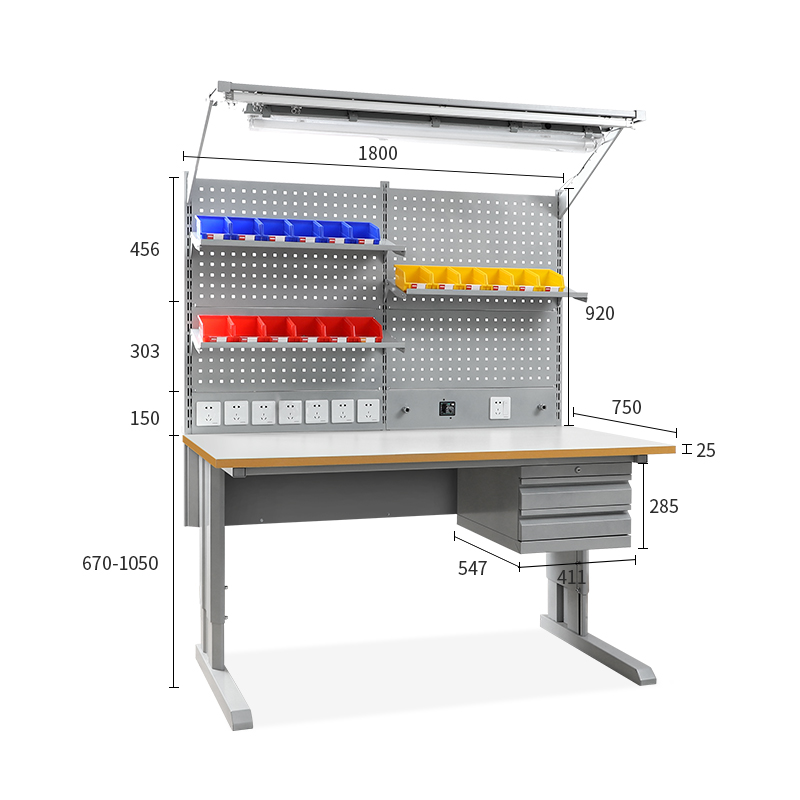

Features of Rockshell Worktops

High-Quality Materials: Our 25mm thick German-imported gray surface with yellow-edged anti-static, wear-resistant countertops is designed for durability. The internal substrate is made of high-strength density board, offering excellent acid and alkali resistance, wear resistance, and good impact resistance.

Permanent ESD Performance: Our industrial-grade anti-static coating provides long-lasting performance in dissipating and releasing static electricity effectively.

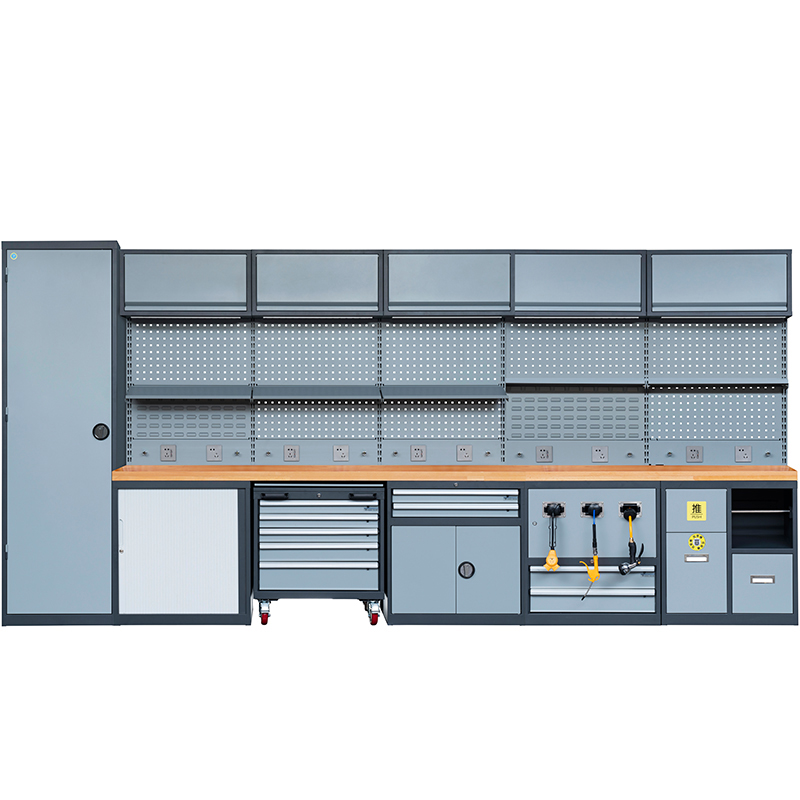

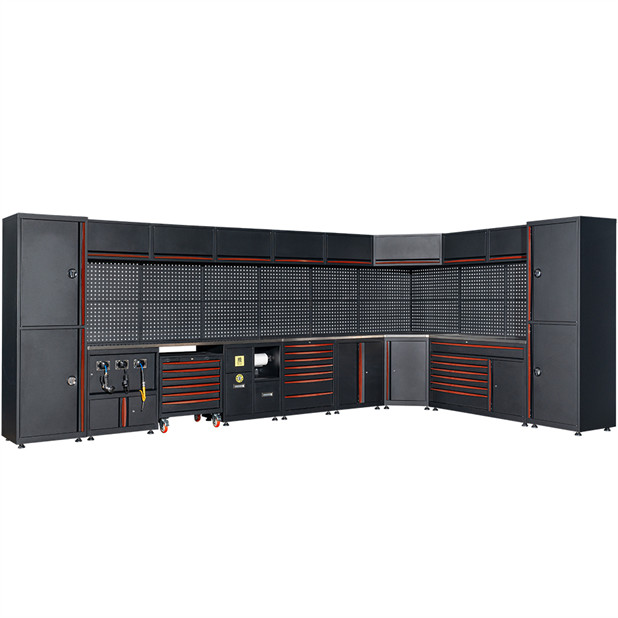

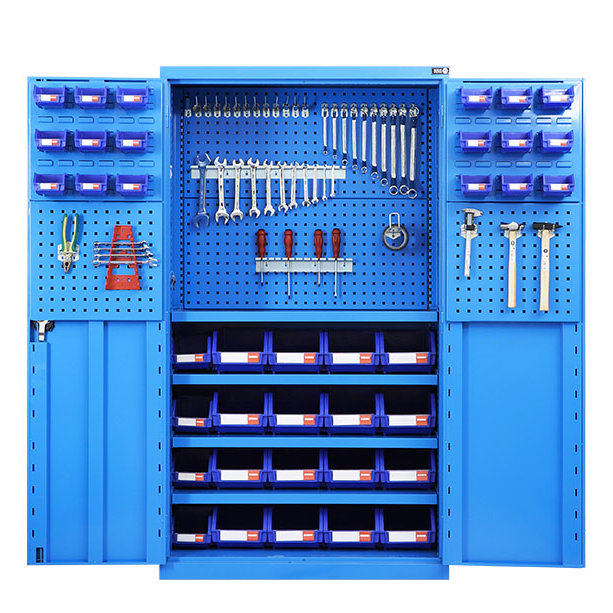

Modular Design: Rockshell workbenches feature a flexible, modular design that allows various accessories to be combined and quickly replaced. This eliminates the need for new equipment purchases when production processes or product lines change. By reconfiguring existing accessories, new production units can be built efficiently, significantly reducing costs.

How to Properly Ground the Anti-Static Workbench?

Static electricity is the “invisible killer” of electronic components, and the grounding line is the core of the anti-static workbench. Improper grounding can lead to equipment damage and even safety hazards.

1. Grounding Preparation

Confirmation of Grounding Requirements: Check whether the workplace has appropriate grounding conditions, such as a dedicated grounding wire or grounding bus.

Selection of Grounding Materials: Choose grounding wire with good conductivity, corrosion resistance, and mechanical strength to ensure long-term stability and reliability.

Prepare Tools: Gather necessary tools such as screwdrivers, scissors, wire strippers, and other tools for grounding wire installation and connection.

2. Grounding Wire Installation

Laying the Anti-static Table Mat: Place the anti-static table mat flat on the workbench to ensure complete coverage of its surface.

Installation of Grounding Wire: Make a small cut in the table mat and insert the star-claw part of the grounding wire. Ensure the star claw is tightly connected to the mat to prevent loosening or detachment.

Connecting Grounding Equipment: Clip the other end of the grounding wire (usually an alligator clip) to an electrostatic discharge (ESD) grounding bus bar or other appropriate grounding equipment to ensure a secure connection.

3. Grounding Resistance Test

Test Equipment Preparation: Prepare a grounding resistance tester and other measuring equipment.

Measurement of Resistance: Use the grounding resistance tester to measure the resistance between the anti-static grounding wire and the anti-static table mat, as well as between them and the earth. Ensure that the resistance is within the permissible range.

4. Maintenance of Grounding

Regular Inspection: Regularly check whether the grounding wire connection is secure and whether there is any breakage or aging.

Cleaning and Maintenance: Clean and maintain the anti-static table mat to keep its surface smooth, avoiding dirt or scratches.