Do-It-Yourself Supplies & Equipment Materials needed for preparation include:

1. Various plywood sizes: refer to the main frame and compartments later.

2. Binding nails: used to secure light components.

3. Screw kit: framework for attaching.

4. Wood glue: additional glue for the frame and lamination.

5. Integrated cabinet hinges: adaptable cabinet door opening and shutting.

6. Easy-to-use cabinet door knobs.

Included are the following tools:

1. Miter saws, table saws, and circular saws: these tools cut wood precisely.

2. Jig: correct the wood and avoid mistakes in processing.

3 . Electric drill: comes with a screw kit for installation and drilling.

4. Stapler: Used for splicing or temporarily repairing lightweight fabrics.

5 . Tape Measure: Check that the pieces fit snugly by measuring the measurements.

6. Hammer and impact driver: to guarantee efficient manufacturing, hammer and tighten screws.

Advantages of self-construction

1. personalized customization: you can design your own cabinets according to specific space and storage needs;

2. Controllable cost: the cost of materials needed for your own DIY is cheaper than steel or other material cabinets;

3. Sense of accomplishment: you can design and make it according to your own style, which is a great sense of accomplishment;

4. Quality control: you can control the selection of materials and production process, so that the cabinets made out of more robust.

Disadvantages of self-construction

1. High production time cost

2. Poor structural stability of wooden structure products, easy to deform

3. The use of time can not be determined, and durability does not meet professional quality standards

4. Single production style, lack of diversity

5. Ordinary people are difficult to operate, and need to know professional carpentry skills

Why choose steel workstation?

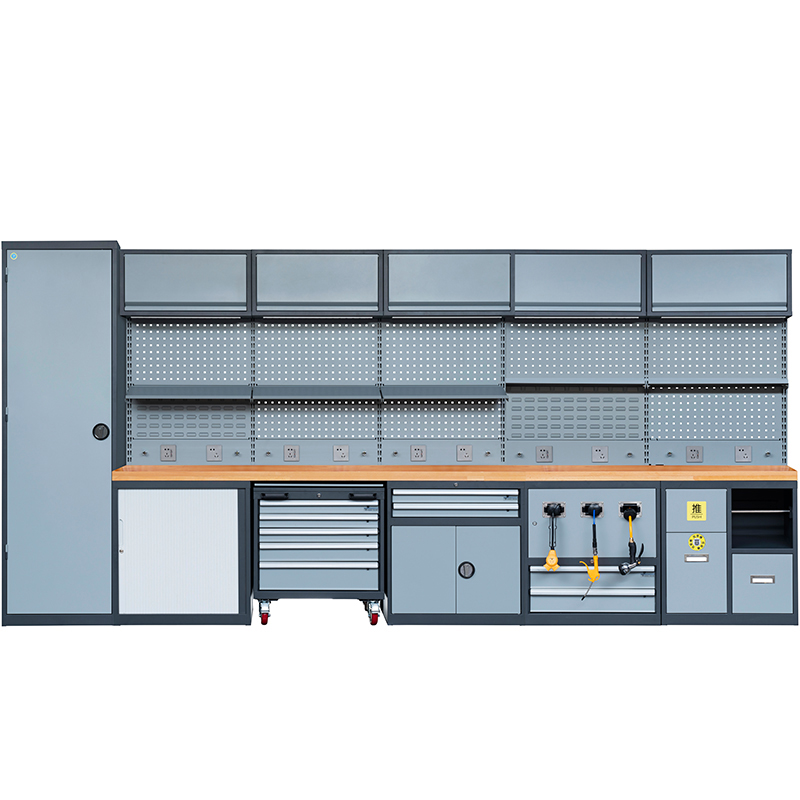

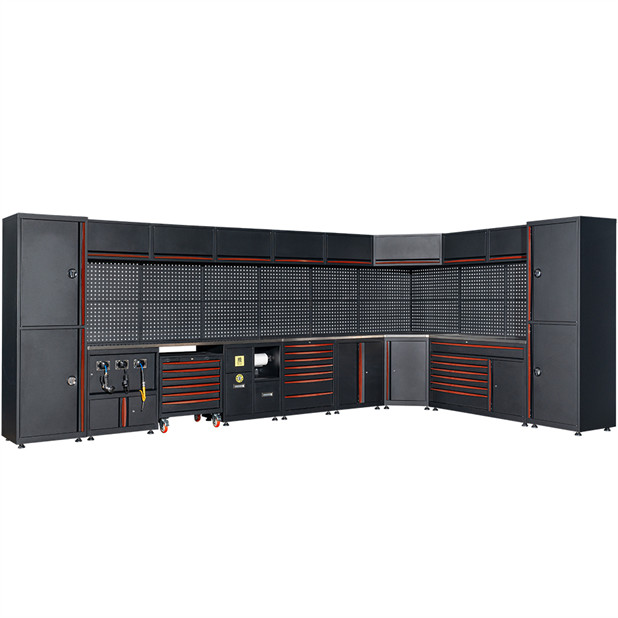

1. Adopt industrial-grade steel: cold-rolled steel plate Q235, sturdy and durable.

2. Pre-assembled and shipped, easy to install, saves time and labor.

3. Customizable internal space and appearance to meet the needs of personalized customization.

4. Use up to 10 years.

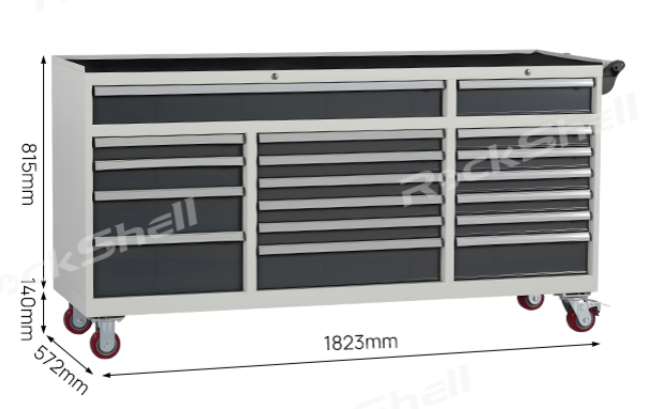

5. Tool cabinet ball bearings, pulling smooth and unhindered.

6. Various styles, sizes, functions and colors are available to meet different needs.

How to clean and maintain the workstation to keep it clean and efficient?

Countertop selection:

Wooden: beech and oak, two choices, high strength, load bearing, suitable for mechanical processing, good impact resistance.

Composite: acid and alkali resistance, wear and oil resistance, impact resistance, and cost-effective.

Stainless steel: high strength, beautiful, acid and alkali resistance, suitable for dustproof and anti-corrosion requirements of high workplaces.

Anti-static: high flatness, vibration absorption, impact resistance, suitable for static-sensitive areas.

Steel Plate: Mechanical link steel plate with welding bolts, wear-resistant, high temperature resistant, and impact resistant.

Fireproof board: fire-resistant and wear-resistant, suitable for assembly and assembly line work in all kinds of factories.

Our countertop thickness is 3cm, which is thicker than the 2.7cm/2.3cm of most e-commerce platforms, with enough material and not easy to deform.

Type Selection:

Modular workstation: you can choose to match according to your needs.

Mobile workstation: flexible and easy to move, suitable for frequent location changes.

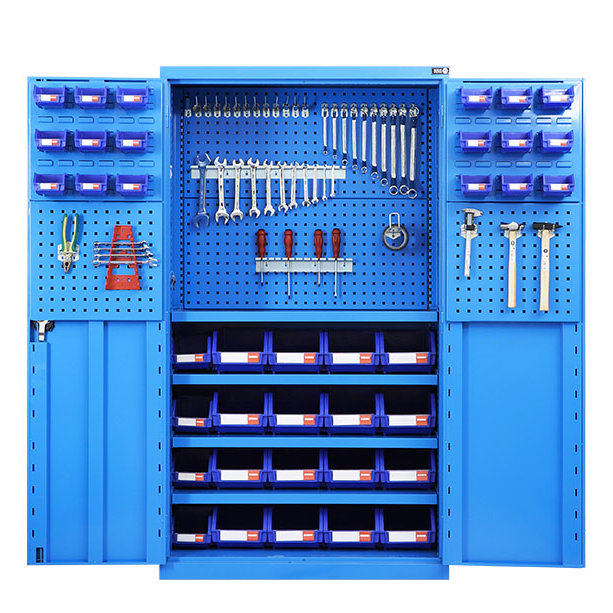

Wall-mounted cabinet: can keep the garage floor clean and save floor space.

Storage needs selection:

According to the type of items stored and the frequency of access to judge, you need to be equipped with what kind of modular workstations. For security reasons, consider lockable cabinets. For heavy tools or bulky items, such as power tools, consider the capacity of the cabinet.

Space and size:

Confirm the length, height, and width of the wall where you need to place it for a better customized storage solution. Smaller garages can use wall-mounted to save floor space, and for larger garages that need it, consider a system of complete cabinets.

Modularized design:

1. Power socket: can be equipped with a European standard socket according to demand.

2. Lamps and lanterns: magnetic adsorption installation is more convenient.

3. Additional cabinet: increase the storage space for large tools.

4. Backboard: Increase the utilization rate of the countertop.

How to pick the most suitable workstation?

Cleaning methods:

1. Deep cleaning requires the use of a soft cloth, with cleaning fluid wipes, to avoid scratching the surface, while avoiding the use of strong acid or alkali containing cleaners, damage to the cabinet material.

2. Daily cleaning using a soft cloth or soft bristle brush, regularly clean countertops, storage cabinet surfaces, and crevices, and remove dust and debris.

Maintenance tips:

1. Categorize and store tools and items to keep them neat and orderly.

2. Use pegboards, drawer shelves, and labeling systems to optimize the use of space and make it easy to find items.

3. Regularly check whether there is any damage to the track lock, hinges, and other parts.

4. Try to keep the workstation environment dry, to avoid humidity leading to shortened life.