OEM & ODM Industrial Drawer Systems Designed for Real Production Environments

In modern factories, workshop drawers are no longer simple storage components. They are a critical part of the industrial workflow, directly affecting productivity, safety, and long-term operating costs.

Compared with standard off-the-shelf cabinets, custom workshop drawer solutions are increasingly preferred by factories that require higher load capacity, better organization, and scalable storage systems.

Why Standard Workshop Drawers Fall Short in Factory Use

Many factories start with standard workshop drawers or tool cabinets. However, after one or two years of real-world use, common problems often appear:

- Tool quantities increase and outgrow the original layout

- Heavy tools exceed drawer load limits

- Fixed drawer dividers limit flexibility

- High-frequency use accelerates wear and deformation

The root cause is simple:

Standard drawers are not designed around real factory workflows.

What Defines a Factory-Grade Custom Workshop Drawer Solution?

A true factory-grade workshop drawer system is not just about changing dimensions. It is designed around actual working conditions, including tool weight, usage frequency, safety standards, and production efficiency.

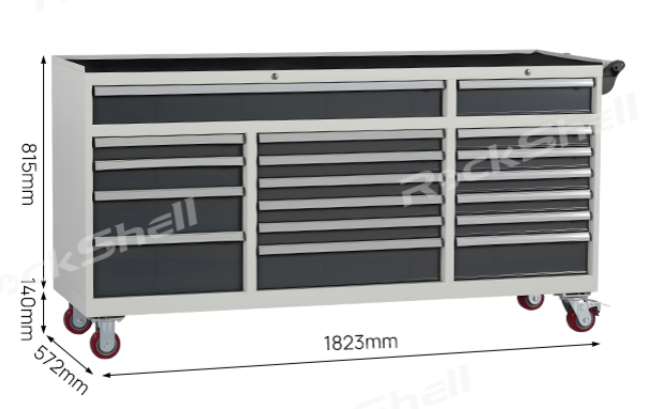

Customization typically includes:

- Drawer width, depth, and height customization

- Load capacity matching real tool weights

- Single-column, double-column, or multi-column layouts

- Adjustable internal dividers and modular accessories

- Integrated locking and safety systems

Key Benefits of Custom Workshop Drawer Systems for Factories

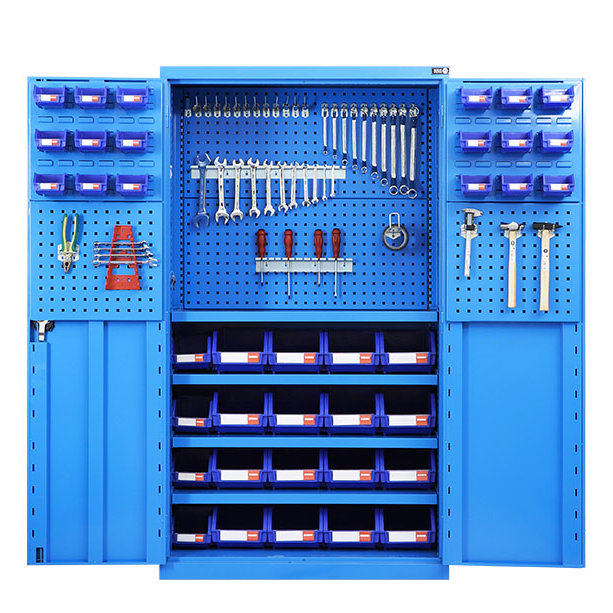

1. Higher Tool Management Efficiency

Custom drawer layouts allow tools to be organized according to real usage patterns:

- Clear tool classification

- Faster access and reduced search time

- Lower risk of tool loss or misplacement

This is especially valuable in maintenance workshops, production lines, and equipment service departments.

2. Load Capacity Built for Industrial Reality

Factory tools are often:

- Heavy

- Frequently used

- Stored long-term in concentrated areas

Custom workshop drawers are engineered with:

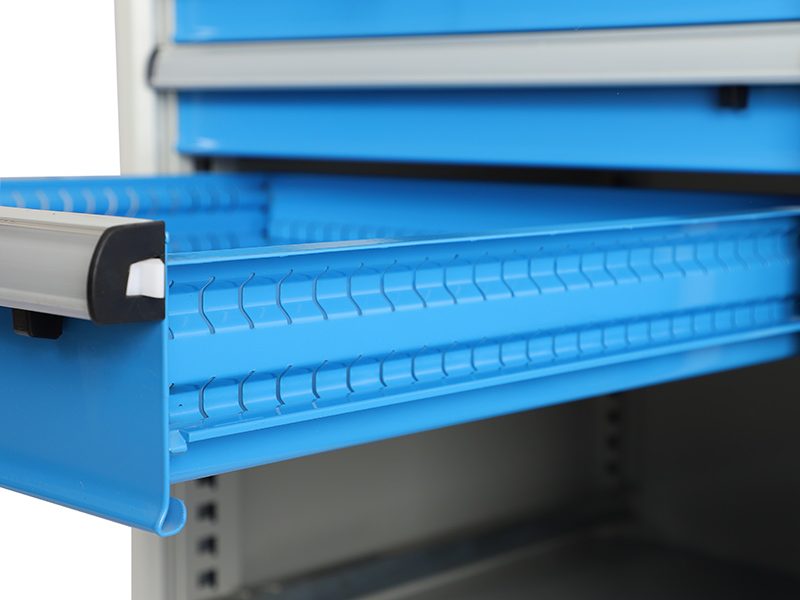

- Reinforced steel drawer structures

- High-load ball bearing slide systems

- Long-term stability without sagging or deformation

3. Improved Safety in High-Intensity Work Environments

Well-designed custom drawer systems help:

- Prevent drawer overload

- Reduce accidental drawer sliding

- Maintain cabinet stability under full load

In multi-shift, high-frequency industrial environments, safety is not optional—it is essential.

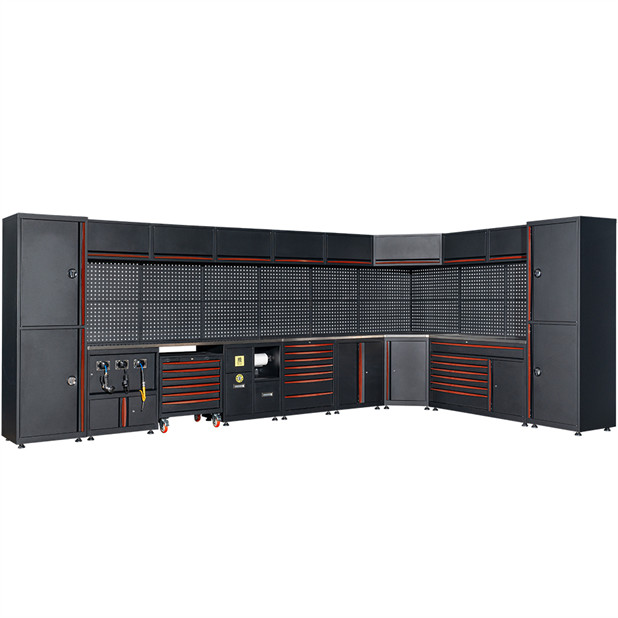

4. Flexible Configuration for Different Workstations

Different factory areas require different drawer solutions:

- Maintenance stations: heavy-duty drawers combined with cabinet doors

- Assembly lines: high-density drawer storage

- Inspection areas: mobile drawer workstations

Customization allows one factory to deploy multiple optimized configurations, instead of forcing all departments into a single standard solution.

Our OEM / ODM Customization Service for Workshop Drawers

To ensure customization is practical, scalable, and production-ready, we provide a complete OEM / ODM service process, covering the entire project lifecycle.

OEM / ODM Service Process

01 | Customer Requirement Assessment & Consultation

We analyze industry type, workstation layout, tool categories, load requirements, and usage frequency.

02 | Design Proposal

Our team develops a workshop drawer solution covering structure, dimensions, load ratings, and layout.

03 | Design Approval & Optimization

Designs are refined to balance performance, manufacturability, and cost efficiency.

04 | Contract Signing & Production Preparation

Technical specifications, delivery schedules, and quality standards are finalized.

05 | Product Manufacturing & Quality Control

All workshop drawers undergo strict structural, load, and durability testing.

06 | Customer Inspection & Delivery

Inspection is supported to ensure full alignment with approved designs.

07 | After-Sales Service Support

Ongoing technical support ensures long-term performance in factory environments.

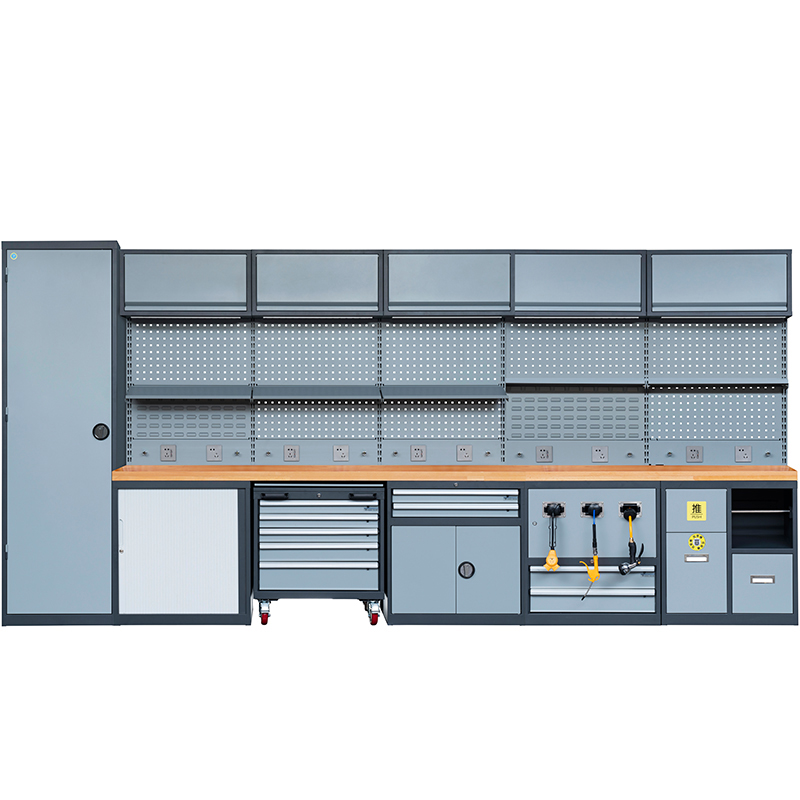

From Custom Drawers to Complete Factory Storage Systems

In many projects, custom workshop drawers are integrated with:

- Industrial tool cabinets

- Mobile tool carts

- Heavy-duty workbenches

Together, they form a complete industrial storage system that supports standardized management while allowing department-level customization.

Conclusion: Custom Workshop Drawers Support Long-Term Factory Growth

Factory tool systems evolve as production processes change and equipment upgrades continue. Only scalable, customizable workshop drawer systems can support this long-term growth.

Custom workshop drawer solutions are not just about solving today’s storage issues—they are a strategic investment in efficiency, safety, and future scalability.

If you are planning to upgrade or standardize your factory storage system, a custom workshop drawer solution is the foundation worth planning carefully.