In aerospace manufacturing and maintenance environments, storage is far more than simply organizing tools and parts—it directly impacts safety compliance, workflow efficiency, and quality control. From precision components and specialized tooling to technical documentation and inspection equipment, every item requires a professional storage system.

So how do aerospace companies choose the right Aerospace Storage Solutions compared to standard industrial cabinets?

Let’s explore the key differences.

Standard Industrial Cabinets vs Aerospace Storage Solutions

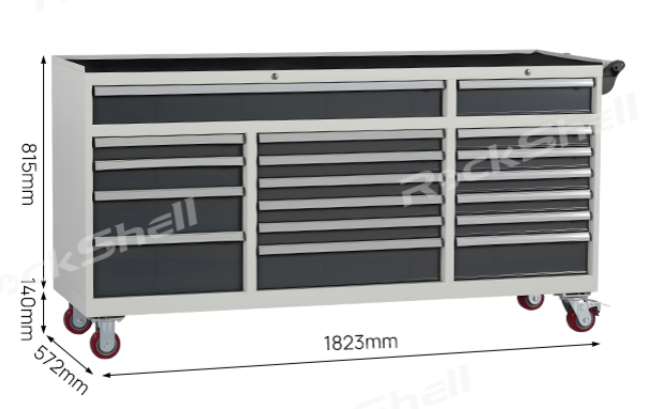

Standard Industrial Cabinets

Designed for general workshop use, standard cabinets typically offer:

- Basic steel construction

- Simple drawer layouts

- Standard locking mechanisms

While cost-effective, they often fall short in aerospace environments due to:

- Limited drawer precision

- Minimal anti-tip protection

- Restricted modular expansion

- Inability to support strict tool control procedures

They are best suited for light-duty workshops or general storage areas.

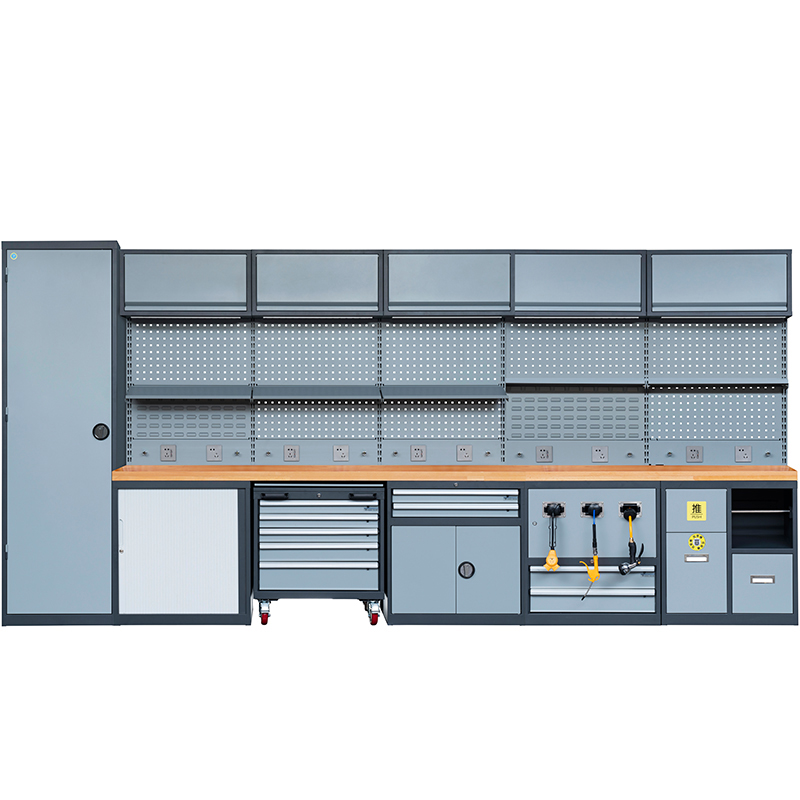

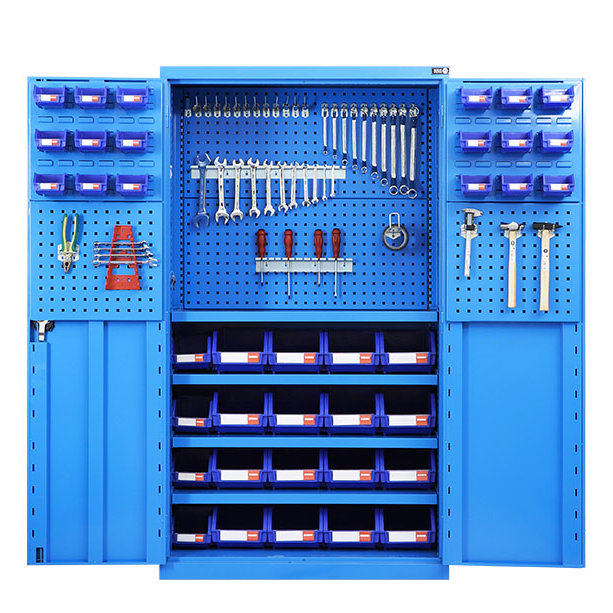

Aerospace Storage Solutions

Purpose-built for high-standard industries, aerospace storage systems emphasize:

- Heavy-duty steel structures with reinforced load-bearing columns

- High-precision drawer slides and stable cabinet frames

- Modular configurations for flexible layouts

- Central locking, self-locking, and optional interlock systems

- Seamless integration into workstation environments

These systems help:

- Improve tool accountability

- Reduce operational risks

- Streamline assembly and maintenance workflows

- Support aerospace quality management requirements

They are widely used on production lines, MRO facilities, and inspection laboratories.

Fixed Warehouse Storage vs Modular Workstation Systems

Traditional Fixed Storage

Centralized warehouse storage typically involves:

- Longer travel distances for tools

- Slower tool circulation

- Workflow bottlenecks during peak operations

This approach limits efficiency in high-tempo aerospace production.

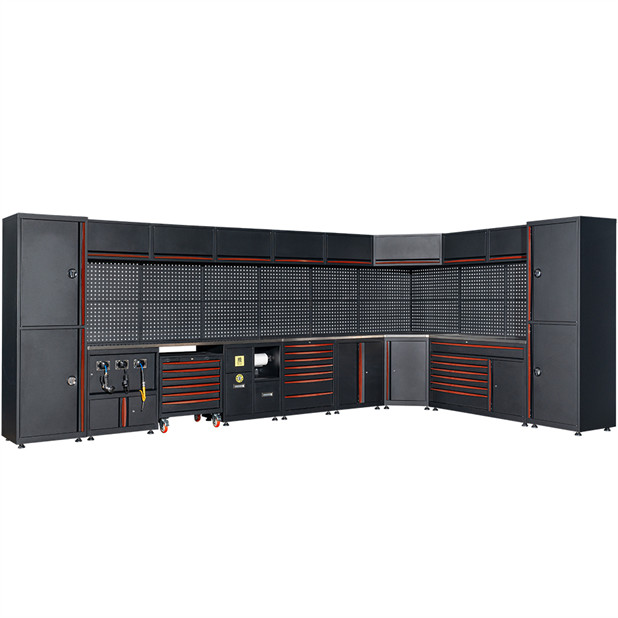

Modular Aerospace Storage Systems

By positioning tool cabinets, drawer units, workbenches, and accessories directly at workstations, modular systems enable:

- Immediate tool access

- Clear organization

- Scalable configurations

This model is ideal for aircraft assembly lines, engine maintenance areas, and precision component stations—significantly improving on-site responsiveness.

Basic Locks vs Advanced Safety Systems

Safety standards in aerospace are uncompromising.

While standard cabinets rely on simple locks, professional Aerospace Storage Solutions typically include:

- Central locking systems

- Self-locking drawers to prevent accidental sliding

- Optional interlock systems that allow only one drawer to open at a time

These features help:

- Prevent tool loss

- Reduce tipping risks

- Enhance operator safety

making them essential for high-reliability environments.

Standard Products vs OEM Customized Solutions

Off-the-shelf cabinets may work for general needs, but aerospace projects often require:

- Custom dimensions

- Specialized drawer inserts

- Dedicated compartment layouts

- Integrated workstation designs

OEM Aerospace Storage Solutions allow layouts to be tailored to specific workflows, delivering better alignment with production processes.

Conclusion: Aerospace Storage Solutions Are Part of the Process—Not Just Cabinets

True Aerospace Storage Solutions are not simply storage products; they are a critical part of aerospace manufacturing and maintenance systems.

Compared with standard industrial cabinets, aerospace storage offers clear advantages in:

- Structural strength

- Safety performance

- Modular flexibility

- Workstation integration

If your operations involve precision assembly, frequent maintenance, or strict quality control, investing in professional aerospace storage solutions will deliver long-term operational value.

📩 Contact us today to explore customized Aerospace Storage Solutions and complete workstation configurations for your projects.