In industrial manufacturing, equipment maintenance, and professional repair environments, efficient tool organization and mobility are essential. An industrial mechanic tool cart is specifically designed to support heavy tools, high-frequency use, and demanding working conditions, making it a core piece of equipment in modern workshops.

This article explains what an industrial mechanic tool cart is, its key advantages, and how to choose the right model for industrial applications.

What Is an Industrial Mechanic Tool Cart?

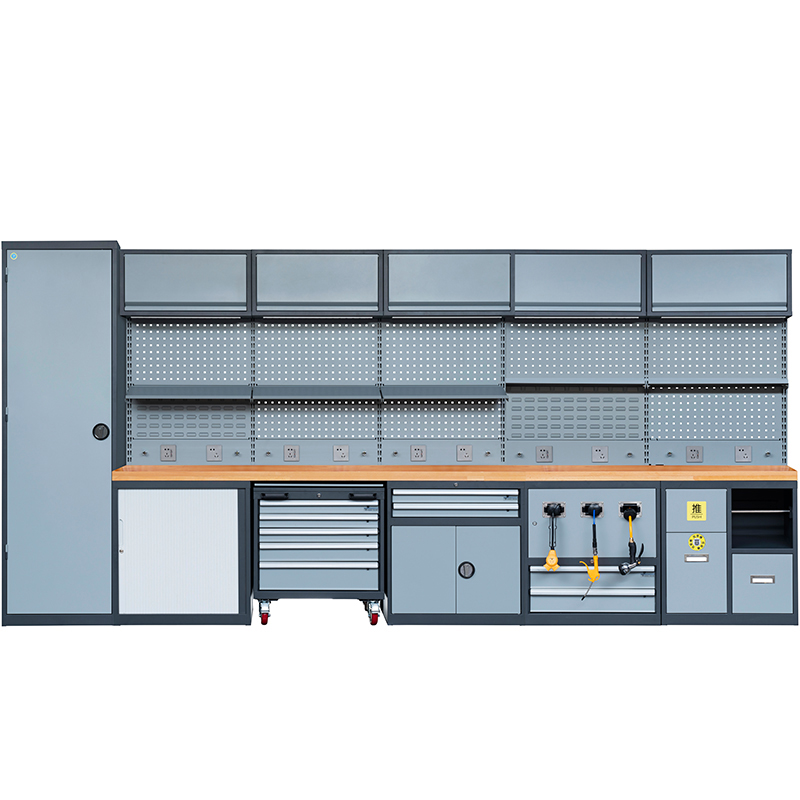

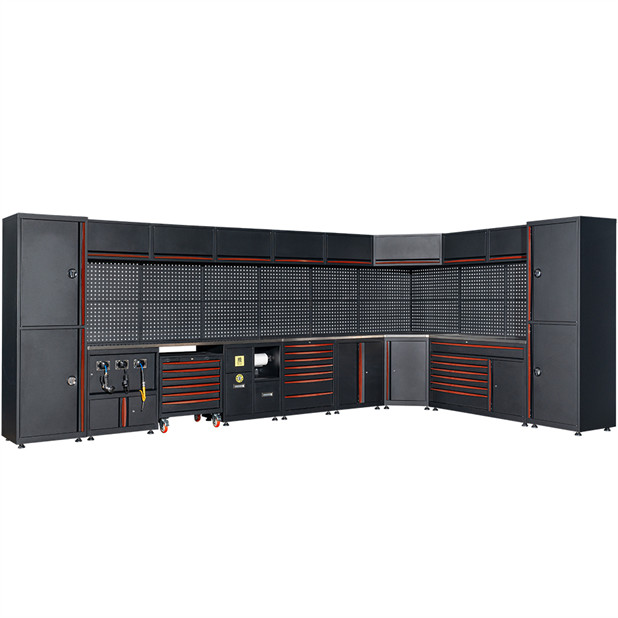

An industrial mechanic tool cart is a heavy-duty, mobile tool storage solution engineered for professional mechanics, maintenance technicians, and industrial engineers.

Unlike standard tool carts, it is built to:

Support heavy tools and equipment

Withstand frequent movement and daily use

Provide stable, secure, and organized storage

It functions not just as a storage unit, but as a mobile tool management system for industrial operations.

Key Benefits of an Industrial Mechanic Tool Cart

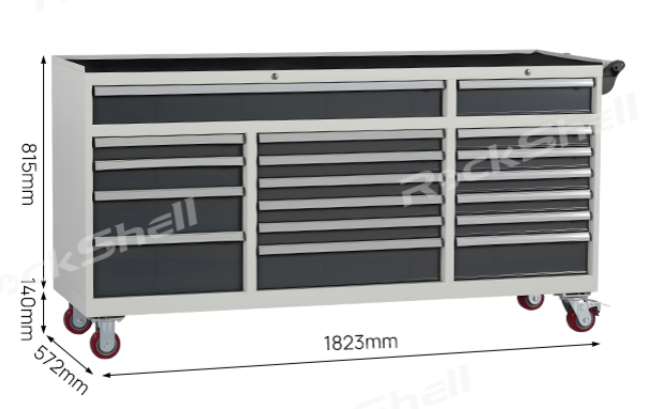

1️⃣ Heavy-Duty Load Capacity for Industrial Tools

Industrial maintenance often involves power tools, torque wrenches, diagnostic equipment, and spare parts that require strong structural support.

A quality industrial mechanic tool cart features:

Thick steel cabinet construction

High load-capacity drawers

Reinforced ball bearing slides for smooth operation under load

This allows heavy tools to be stored safely in a centralized location.

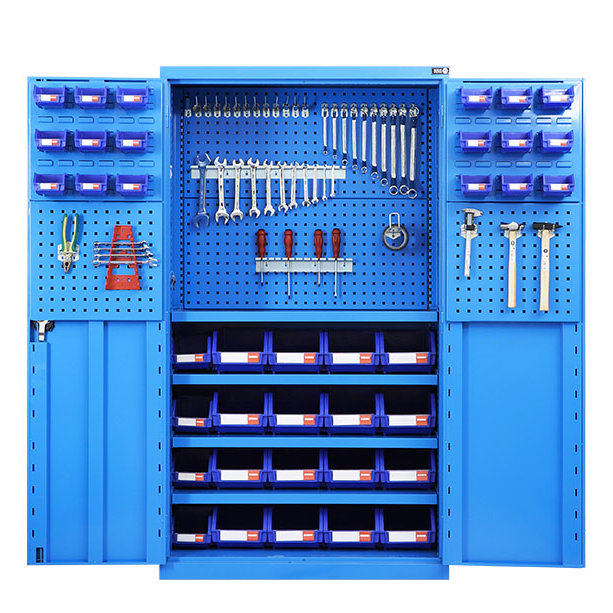

2️⃣ Multi-Drawer Design for Efficient Tool Organization

Drawer-based storage improves workflow and reduces downtime.

Benefits include:

Clear tool categorization

Multiple drawer height options

Optional drawer dividers for customized layouts

High-density drawer designs help maximize storage capacity within a compact footprint.

3️⃣ Stable Mobility for Workshop Environments

Mobility is critical in industrial settings where tools must move between workstations.

Industrial mechanic tool carts are typically equipped with:

Heavy-duty, silent casters

Two swivel casters with brakes and two fixed casters

High overall load capacity for safe movement

Even when fully loaded, the cart remains easy to maneuver and stable.

4️⃣ Enhanced Safety and Security Features

Safety is a key requirement in industrial workplaces.

Common safety features include:

Centralized mechanical locking systems

Self-locking drawers to prevent accidental opening

Enclosed steel cabinet design to protect tools

These features help prevent tool loss and improve workplace organization.

Typical Applications

Industrial mechanic tool carts are widely used in:

Manufacturing plants

Industrial maintenance departments

Automotive and heavy equipment repair

Service bays and production lines

Warehousing and equipment inspection areas

They are designed for environments that demand durability, reliability, and efficiency.

How to Choose the Right Industrial Mechanic Tool Cart

When selecting an industrial mechanic tool cart, consider:

Cabinet steel thickness and structural strength

Drawer load capacity and slide type

Number of drawers and internal customization options

Caster load rating and braking system

Availability of custom sizes and configurations

Choosing the right tool cart improves productivity while reducing long-term maintenance costs.

Conclusion: A Core Tool for Professional Maintenance

An industrial mechanic tool cart is more than a storage solution—it is a foundation for safe, efficient, and professional maintenance work.

With heavy-duty construction, organized drawer systems, and secure mobility, it supports demanding industrial environments and long-term use. For professionals who rely on their tools every day, investing in the right industrial tool cart delivers lasting value.