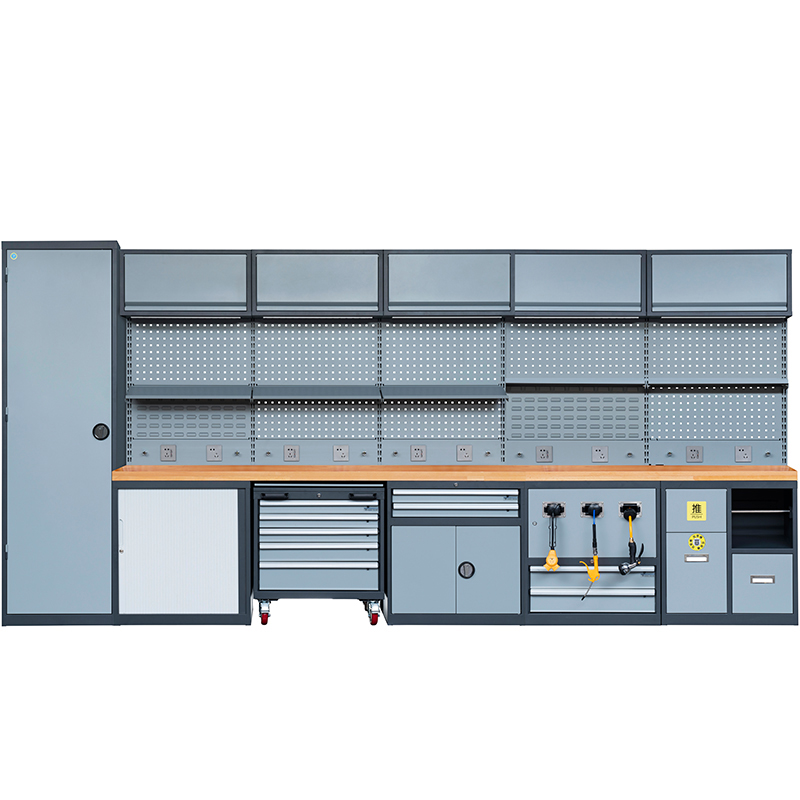

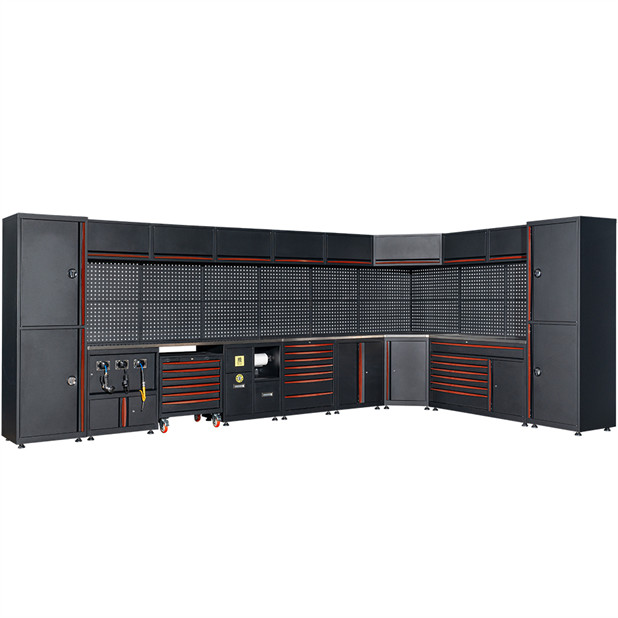

By using 5S management on the shop floor, companies can improve competitiveness in the fast-paced world of manufacturing and processing by improving a clean, efficient, and safe workspace. 5S management is especially important for our key products, such as combination cabinets, tool carts, and tool cabinets. Let’s analyze what 5S is, why it’s important, and how to make it work on your factory floor.

What is 5S Management?

The 5S system originated in Japan and is widely used in lean manufacturing. It strives to create an organized and disciplined work environment by following five basic steps:

Sort (Seiri)

Sort items that need to be organized and remove all unnecessary items. Keep only frequently used tools and materials to minimize the amount of space occupied.

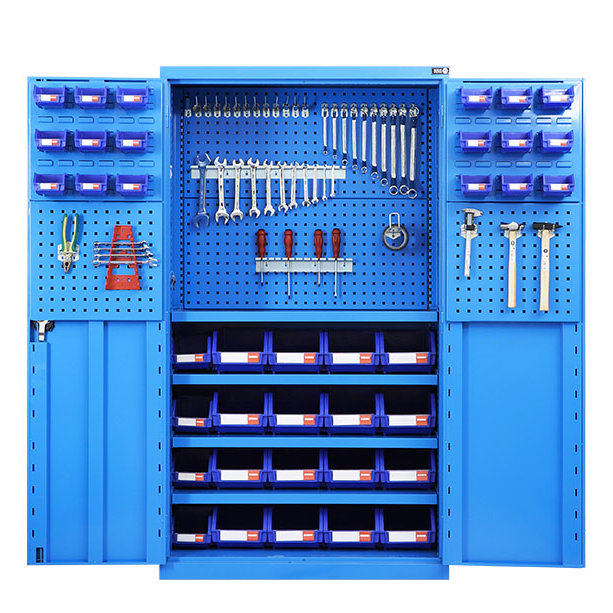

Set in Order (Seiton)

Arrange tools neatly for easy access. Use labels, foam tool mats, and categorize blocks and place them in designated storage areas to ensure that all tools are clearly located and can be found immediately.

Shine (Seiso)

Clean your workspace frequently to maintain organization. It’s not just about aesthetics; removing dust and dirt protects equipment and extends the life of your tools.

Standardize (Seiketsu)

Establish routines and guidelines for organization and cleaning. Assign responsibilities and create checklists or work guidelines that everyone can follow.

Sustain (Shitsuke)

Build long-term discipline by developing employees who value order and efficiency. Provide ongoing training to encourage employees to follow rules and regulations.

Why apply 5S to tool cabinets and tool cart storage?

Optimize Space

By removing clutter and organizing efficiently, floor and storage space can be maximized, which is critical in tight shop environments.

Increase Productivity

Tools are easier to find, which reduces downtime and streamlines daily operations, helping to make your business more competitive.

Better product quality

A clean workspace minimizes the risk of contamination that can affect precision machining and helps save money by maintaining production equipment.

Improved workplace safety

Fewer tripping hazards and clearer pedestrian pathways keep workers safe during production and improve operational safety.

Stronger professional image

Creates a comfortable factory environment and enhances corporate image. A well-organized 5S management system communicates to customers that the factory cares about quality at all levels.

Steps to Successful 5S Implementation

Establish a 5S team

Gather key people to lead the program. A manager organizes a management team, with the participation of department supervisors and front-line employees, to plan, implement, check, and improve 5S management.

Develop clear guidelines

Define the goals of 5S management and assign responsibilities to specific measures, such as standards and inspection methods, to ensure that the system can be fully implemented in place.

Conduct training professional team

To explain to employees the importance of 5S and how to apply it, to improve the overall awareness of 5S management, and to motivate employees to actively participate.

Implement 5S management

Implement 5S management gradually according to the steps of organizing, straightening, cleaning, standardizing,g and maintaining.

Continuous Monitoring and Improvement

Regularly review and adjust according to practice. 5S management is not a one-time project, but a mode of thinking for continuous improvement. Identify problems in a timely manner and continuously improve the methodology.

A cluttered and unorganized tool area not only causes trouble but also poses a potential hazard to employee safety. Adopting 5S management not only organizes everything but also lays the foundation for more efficient, safer, and higher-quality operations.

So , whether you’re starting from scratch or looking to optimize your existing space, 5S management is the go-to strategy for creating a factory/workshop that really works.

Follow us for more workshop management tips and product information!